I gave up on those for time being after 4 failed prints and a decent amount of wasted filament. I'll revisit that after I have more experience making smaller items first. Last few days have been pretty productive tho and should be on the right track.Your prototypes look great! I know how fussy this can be and how many dozens of tweaks and retweaks you have had to do. Sign me up for a racker stacker!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3d printed rack (1 Viewer)

- Thread starter Sparkynutz

- Start date

You can probably get away with even less here and still have a sturdy piece.Reduced walls to 5 and infill to 30% but still solid and heavy.

I've gone as low as 3 walls but then sometimes I see slight color variations where infill is. I can certainly pinch pennies if I end up selling to buyer that may want to save a buck or need the weight savings.You can probably get away with even less here and still have a sturdy piece.

For my personal racks that only move around the room I kinda like the extra weight.

MichaelBubly

Flush

My guess is something to do with bed leveling or z-offset if you are using a BLTouch. Looks like the walls have slight inconsistencies in the layers which could be from the bed being slightly out of level. Could also experiment with different nozzel temps and look into calibrating your flow rate to clean up the layers. Another really important aspect can be moisture in the filament. I bought a filament dryer which has really helped print consistency.I've gone as low as 3 walls but then sometimes I see slight color variations where infill is. I can certainly pinch pennies if I end up selling to buyer that may want to save a buck or need the weight savings.

For my personal racks that only move around the room I kinda like the extra weight.

I think my typical is 2 walls at 25% infill for parts with function like racks or trays and 18% for aesthetic stuff. Usually with the zig zag infill in cura. It's a major PITA trying to figure out what is causing failed prints at the beginning though. But once you dial your printer in you should get pretty much 100% success rate on simple prints with clean layers, a high print speed, and using the least amount of filament possible.

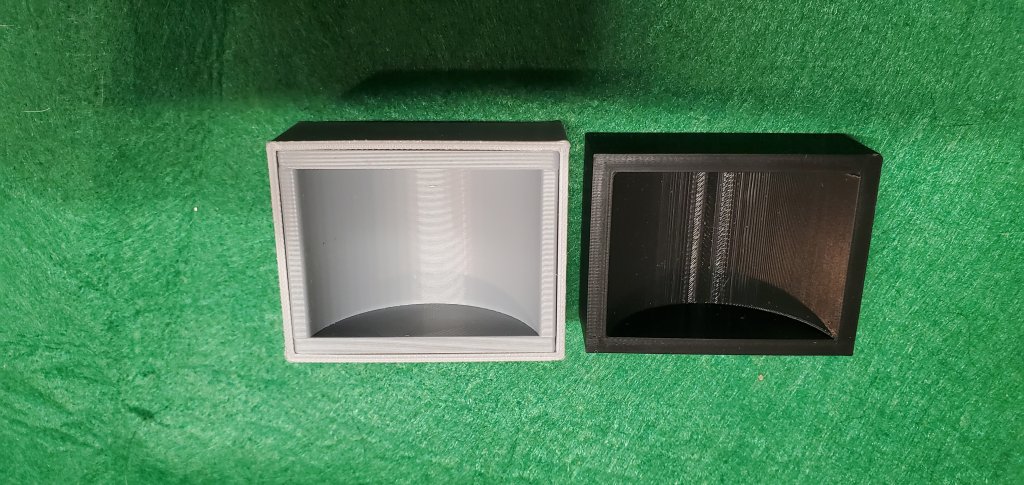

1pc tray next to my new 4 part tray with curve printed flat. It turned out perfect.

Not a blemish on it with a smooth curve.

Was going to glue them inside outer box but fits snug enough that I didn't need to.

If anything I could sand the sides of the bottom to give me just a hair more room to put it together with the sides.

I might try a 2 part tray without adding sides to see how that looks.

Not a blemish on it with a smooth curve.

Was going to glue them inside outer box but fits snug enough that I didn't need to.

If anything I could sand the sides of the bottom to give me just a hair more room to put it together with the sides.

I might try a 2 part tray without adding sides to see how that looks.

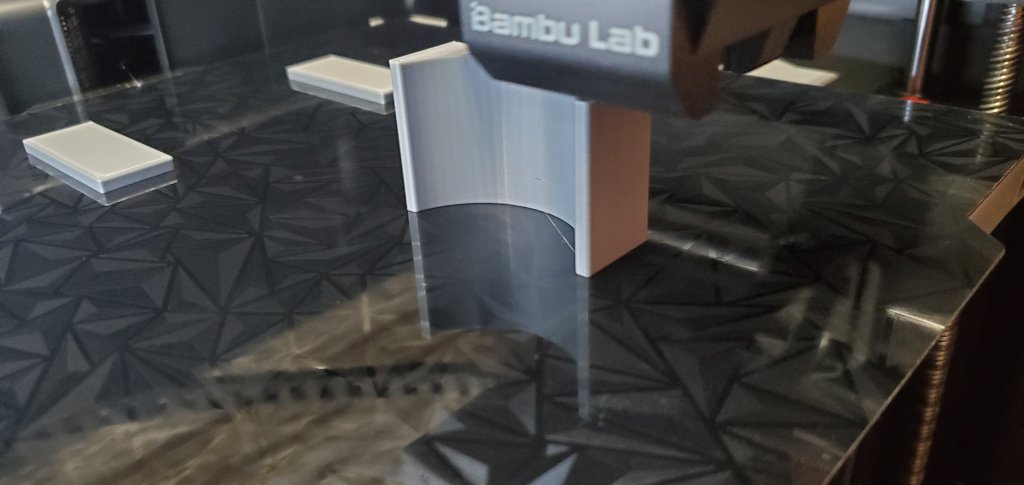

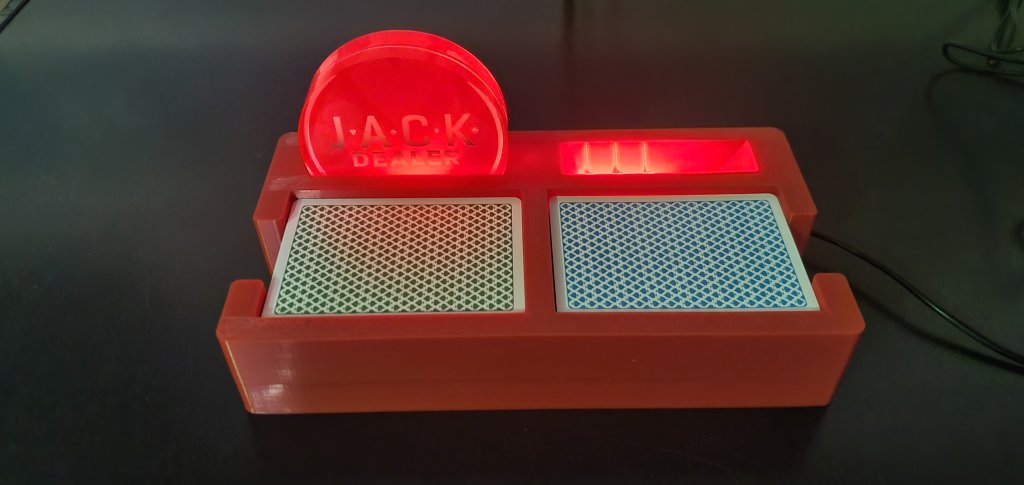

First finished prototype of 5parky Stacker

May not be light and fancy with suits in it but it seems to do the job.

The handle feels and looks better than I thought it would. Feels heavy duty compared to the ones I've seen on here.

Definitely needs a few tweaks to print settings yet but cant complain.

Thoughts for any changes?

Was 4hr print time, After a few tweaks I shaved off 28 minutes on the one printing now.

May not be light and fancy with suits in it but it seems to do the job.

The handle feels and looks better than I thought it would. Feels heavy duty compared to the ones I've seen on here.

Definitely needs a few tweaks to print settings yet but cant complain.

Thoughts for any changes?

Was 4hr print time, After a few tweaks I shaved off 28 minutes on the one printing now.

I like it! When can I buy one?

Hoping by End of January to have a membership and have enough printing stocked up to start selling.I like it! When can I buy one?

Love it. I’m in for one!

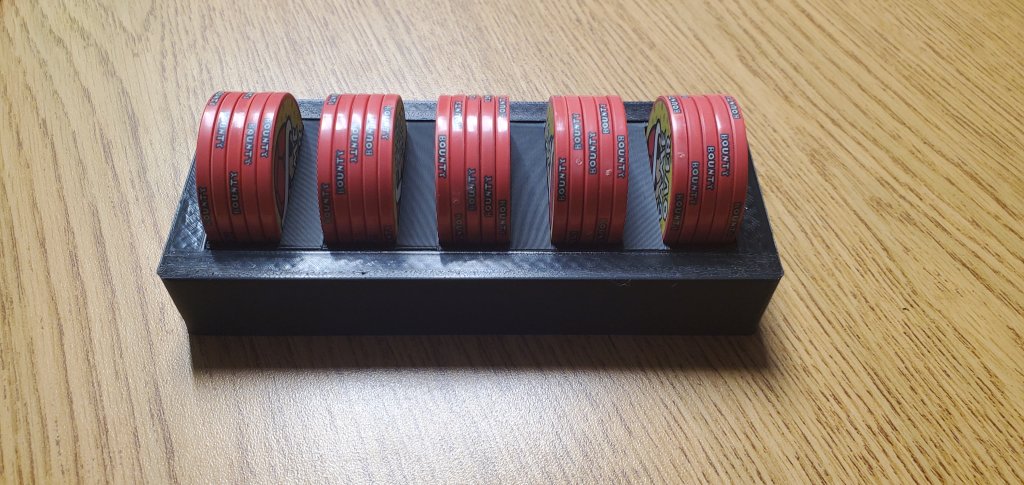

Newest print-

6pc assembled bounty chip holder.

If you look close you can tell where each part is. I really like the bottom finish printing like this but sanding to fit perfect then assembling is a pita.

6pc assembled bounty chip holder.

If you look close you can tell where each part is. I really like the bottom finish printing like this but sanding to fit perfect then assembling is a pita.

2 color silk made some pretty unique looking racks.

ChicagoAlderman

Sitting Out

@Sparkynutz Have you investigated poured resin molds based on your final designs? Material cost is similar but I think the resin has more strength? Two part molds may eliminate some material cost, if you model voids in underside supports, as well? It may add to the consistency of resulting product, in that there are no moving parts, and I would think you could make a few molds off the prototypes to increase production volume. Custom colors outside of your filament choices may be an option as well? Swirled color effects from mixed color resins are a possibility?

ChicagoAlderman

Sitting Out

Multiple pours could match custom colors for chips, and a clear truly transparent version could be produced. UV hardening of layers might lower production time, as well?

Yes, I have thought about this just haven't tried yet. A good friend of mine does epoxy chess sets among other things said he'd help me get started. Unfortunately he moved about an hour away and our schedules just haven't jived.... yet.@Sparkynutz Have you investigated poured resin molds based on your final designs? Material cost is similar but I think the resin has more strength? Two part molds may eliminate some material cost, if you model voids in underside supports, as well? It may add to the consistency of resulting product, in that there are no moving parts, and I would think you could make a few molds off the prototypes to increase production volume. Custom colors outside of your filament choices may be an option as well? Swirled color effects from mixed color resins are a possibility?

ChicagoAlderman

Sitting Out

I dare you to try, then!Yes, I have thought about this just haven't tried yet.

Seriously the stress of watching a print vs. watching "paint dry" is worth a try.

Newest addition.

Wish I had two buttons to go in it tho.

Wish I had two buttons to go in it tho.

Stocking up. Sparky Stackers pretty well dialed in

Made some 12 and 15 chip shuffle stack trays too.

Made some 12 and 15 chip shuffle stack trays too.

Any chance you can make flattening racks like these?

https://www.pokerchipforum.com/thre...r-10-39mm-chip-11-43mm-ceramic-blanks.105822/

https://www.pokerchipforum.com/thre...r-10-39mm-chip-11-43mm-ceramic-blanks.105822/

What is the function or purpose of the tan part on the bottom?Any chance you can make flattening racks like these?

https://www.pokerchipforum.com/thre...r-10-39mm-chip-11-43mm-ceramic-blanks.105822/

Decorative I suppose. I’ve never had one of these so I can’t say for sure.What is the function or purpose of the tan part on the bottom?

Stocking up. Sparky Stackers pretty well dialed in

Made some 12 and 15 chip shuffle stack trays too.

View attachment 1263572

I would be interested in one of these if it were the same width, length, and height as a Justin rack. I would be SUPER interested if it had nibs on the bottom that locked into the Justin rack recesses.

So glad to see a 3d print Maker is active on this forum!

What is the function or purpose of the tan part on the bottom?

I have one and the green is what really matters

That is still on the list along with adapter plates that go between 40mm and 43mm so they stack and lock.I would be interested in one of these if it were the same width, length, and height as a Justin rack. I would be SUPER interested if it had nibs on the bottom that locked into the Justin rack recesses.

View attachment 1263580

So glad to see a 3d print Maker is active on this forum!

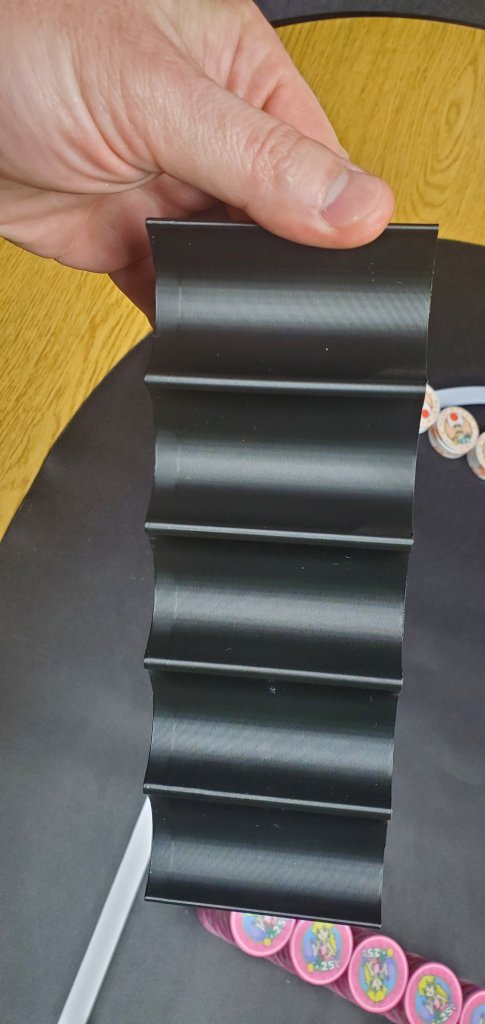

Here is my latest design.

Whatcha think?

80mmx12

65mm is next.

Whatcha think?

80mmx12

65mm is next.

mcfilthy

High Hand

Stocking up. Sparky Stackers pretty well dialed in

Made some 12 and 15 chip shuffle stack trays too.

Stop it, I don't need to spend $ on a 3d printer too.

Charly

3 of a Kind

3D printing offers so much confort to our chips my god !! ... Thank you so much @BearMetal for your time and advises. It's a long process but the doors are open and infinite ...@Sparkynutz ... Consider this decision carefully. I've been 3D printing things on in here for members for years and I've learned one thing: 3D printing and being a vendor will become a full time job.

It takes like 10 hours to print a single side of rack stacker. I've had printers catch fire, so my advice is to always be home and attentive while a print is running (not something most people can do).

If you're looking at printers, I would consider the Bambu Labs for it's sheer speed, but be prepared to spend $2k+.

Postoakpoker

Pair

Love this design, would definitely buy one when available.

Similar threads

- Replies

- 151

- Views

- 4K

- Replies

- 1

- Views

- 499