Turning the column

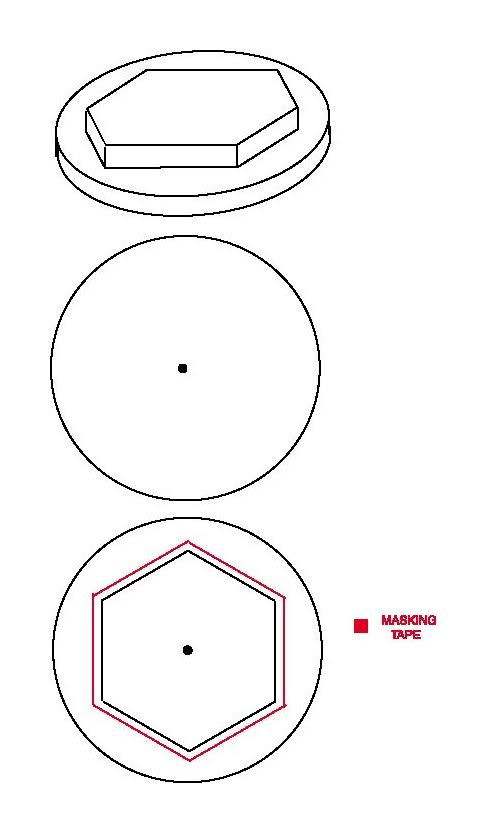

Once the assembled columns have set, you're ready to turn them on a lathe. To mount the column securely, you'll need to construct lathe mounts. Some sources say you can screw the mounts directly to the column, but I prefer to make them to fit tightly into the column. The following diagram shows how they look.

To make the upper part, reach inside the column and trace the interior shape on a piece of wood. Then trim it down and sand until the piece just fits inside the column. Locate and mark the center point of the column on this piece. Attach it to another piece which will serve as a base with screws. This can be a circle, hexagon or square; shape isn't important.

Finish drilling the center point completely through the mount; this serves as your reference. Make mounts for each side for each column. I wrapped masking tape around the top piece to get it to fit snugly. You'll be able to remove and replace the mounts whenever you want easily this way.

One mount will use the same connection (a mandrel??? - I don't know its name - the same one that secures a bowl blank) to the lathe's spindle and the other mount uses a live center. Don't use a dead center, since this will enlarge the center point of the mount and consequently loosen during turning. Attach the mandrel to the mount with wood screws.

TIP:

Mark each lathe mount and column with felt tip marker for reference.

Mark each column (I and II) and also the top (t) and bottom(b).

After you have them fitted, mark the side of the column and corresponding side of the lathe mount to match up. This way, you'll be able to remove and replace the lathe mounts as often as needed. You want the ability to turn and sand the column for touch up, etc. and remove and replace the mounts. By maintaining the original center points the same for each time on the lathe, you will get a concentric turn.

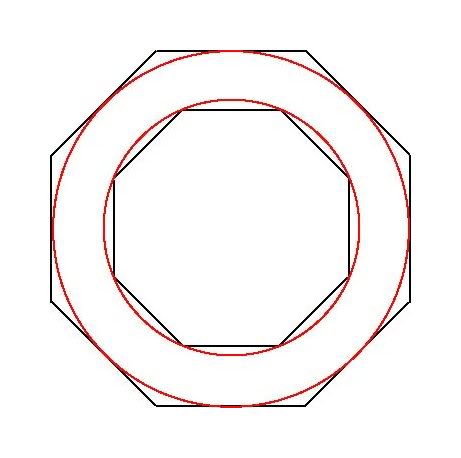

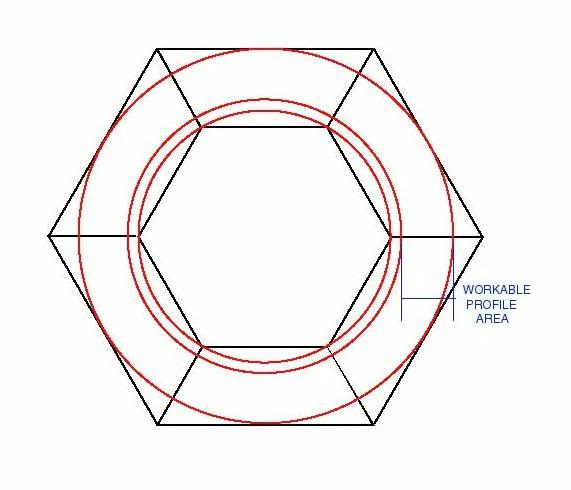

You can see how turning varies for a six-sided column and an eight-sided column and also how the working profile area depends on the number of sides and thickness of the staves. The advantage to using an octagon design is that there is less material to remove.

Before you begin to make the profile, you'll need to turn the middle portion of the column so the cross-section is circular. The lathe I used had an attachment with a knife edge. It ran on a track and I could crank one handle to move it laterally and another handle to move the cutting edge inwards and outwards. This was a very slow process, but the middle came out nice and round.

Design your profile for the column's center, basing it on the workable area. You cannot turn all the way down to the innermost circle, since the column would disintegrate. Retain enough dimension for the column to keep its strength.

Before you begin turning...

TIP:

THE LARGER THE DIAMETER BEING TURNED, THE SLOWER THE SPEED OF THE LATHE.

SET THE SPEED OF THE LATHE AT ITS LOWEST SETTING BEFORE LOADING THE COLUMN. DO NOT LOAD THE COLUMN AND ADJUST THE SPEED DOWNWARDS.

ALWAYS SET THE SPEED OF THE LATHE LOW AND WORK YOUR WAY UP IF POSSIBLE .

Before you turn the lathe on, be completely sure the piece is mounted securely in the lathe. Check the live point and make certain it is secure. If you load the column and turn it on while it's set at a high speed, you're looking at a dangerous situation. If the column is slightly loose, it may work itself free and fly out, even at lower speeds. A flying column with this much mass and can cause serious injury as well as significant damage to surrounding property. I'm not kidding.

GENERAL SAFETY TIPS:

Eye protection is a necessity when turning.

Respiratory equipment is also important when turning.

Gloves should not be used with rotating equipment, since there's always a risk of getting tangled in the machine.

DO NOT WEAR ANY RINGS WHILE OPERATING A LATHE!

Repeat the process of turning and sanding for each column until you are satisfied with the results. You can turn a portion of the upper and lower areas for the shoulders. You can get these areas 95% done and finish the remainder with hand tools. Be careful when turning these areas, because it's easy to chip the edges. Give yourself plenty of margin to work with.

TIP:

Always make sure your chisels are sharp when turning. A dull chisel makes for lots more sanding. Sharpen chisels continually during the turning process.

The columns are now ready for the next step; adding the legs.

Once the assembled columns have set, you're ready to turn them on a lathe. To mount the column securely, you'll need to construct lathe mounts. Some sources say you can screw the mounts directly to the column, but I prefer to make them to fit tightly into the column. The following diagram shows how they look.

To make the upper part, reach inside the column and trace the interior shape on a piece of wood. Then trim it down and sand until the piece just fits inside the column. Locate and mark the center point of the column on this piece. Attach it to another piece which will serve as a base with screws. This can be a circle, hexagon or square; shape isn't important.

Finish drilling the center point completely through the mount; this serves as your reference. Make mounts for each side for each column. I wrapped masking tape around the top piece to get it to fit snugly. You'll be able to remove and replace the mounts whenever you want easily this way.

One mount will use the same connection (a mandrel??? - I don't know its name - the same one that secures a bowl blank) to the lathe's spindle and the other mount uses a live center. Don't use a dead center, since this will enlarge the center point of the mount and consequently loosen during turning. Attach the mandrel to the mount with wood screws.

TIP:

Mark each lathe mount and column with felt tip marker for reference.

Mark each column (I and II) and also the top (t) and bottom(b).

After you have them fitted, mark the side of the column and corresponding side of the lathe mount to match up. This way, you'll be able to remove and replace the lathe mounts as often as needed. You want the ability to turn and sand the column for touch up, etc. and remove and replace the mounts. By maintaining the original center points the same for each time on the lathe, you will get a concentric turn.

You can see how turning varies for a six-sided column and an eight-sided column and also how the working profile area depends on the number of sides and thickness of the staves. The advantage to using an octagon design is that there is less material to remove.

Before you begin to make the profile, you'll need to turn the middle portion of the column so the cross-section is circular. The lathe I used had an attachment with a knife edge. It ran on a track and I could crank one handle to move it laterally and another handle to move the cutting edge inwards and outwards. This was a very slow process, but the middle came out nice and round.

Design your profile for the column's center, basing it on the workable area. You cannot turn all the way down to the innermost circle, since the column would disintegrate. Retain enough dimension for the column to keep its strength.

Before you begin turning...

TIP:

THE LARGER THE DIAMETER BEING TURNED, THE SLOWER THE SPEED OF THE LATHE.

SET THE SPEED OF THE LATHE AT ITS LOWEST SETTING BEFORE LOADING THE COLUMN. DO NOT LOAD THE COLUMN AND ADJUST THE SPEED DOWNWARDS.

ALWAYS SET THE SPEED OF THE LATHE LOW AND WORK YOUR WAY UP IF POSSIBLE .

Before you turn the lathe on, be completely sure the piece is mounted securely in the lathe. Check the live point and make certain it is secure. If you load the column and turn it on while it's set at a high speed, you're looking at a dangerous situation. If the column is slightly loose, it may work itself free and fly out, even at lower speeds. A flying column with this much mass and can cause serious injury as well as significant damage to surrounding property. I'm not kidding.

GENERAL SAFETY TIPS:

Eye protection is a necessity when turning.

Respiratory equipment is also important when turning.

Gloves should not be used with rotating equipment, since there's always a risk of getting tangled in the machine.

DO NOT WEAR ANY RINGS WHILE OPERATING A LATHE!

Repeat the process of turning and sanding for each column until you are satisfied with the results. You can turn a portion of the upper and lower areas for the shoulders. You can get these areas 95% done and finish the remainder with hand tools. Be careful when turning these areas, because it's easy to chip the edges. Give yourself plenty of margin to work with.

TIP:

Always make sure your chisels are sharp when turning. A dull chisel makes for lots more sanding. Sharpen chisels continually during the turning process.

The columns are now ready for the next step; adding the legs.