alpine0000

Pair

I recently received my 44mm chip order from CPC, and bought a rack online for them, and I couldnt fit 20 chips in each barrel of the rack.

After searching online, and some back and forth with @David Spragg (and some members here), I learned that there aren't any chip racks on the market that will hold 44mm CPC chips. My only option is custom wood racks, or custom 3D-printed racks, neither of which I like the look of.

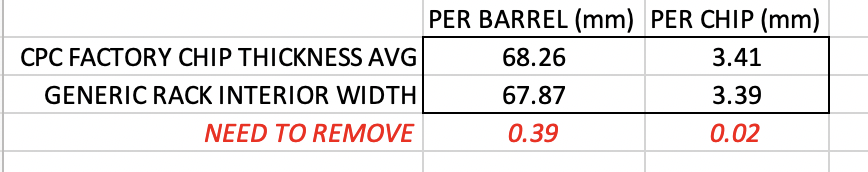

These generic chip racks are 67.87mm interior width.

And a barrel of CPC chips average about 68.26mm thick (too thick for the racks)

So after some thought and some math, I realized that these chips weren't too far off from fitting, and only a small amount would need to be removed from each chip for them to fit. With my calipers, I was averaging 3.41mm per chip from CPC, but they only needed to be down around 3.39mm to fit, so I would only need to remove .02mm on average (a human hair is about .06mm). The 3.41mm from the factory is "average" though. Some chips were below the 3.39mm already, and some of them were as high as 3.48 or even 3.52mm.

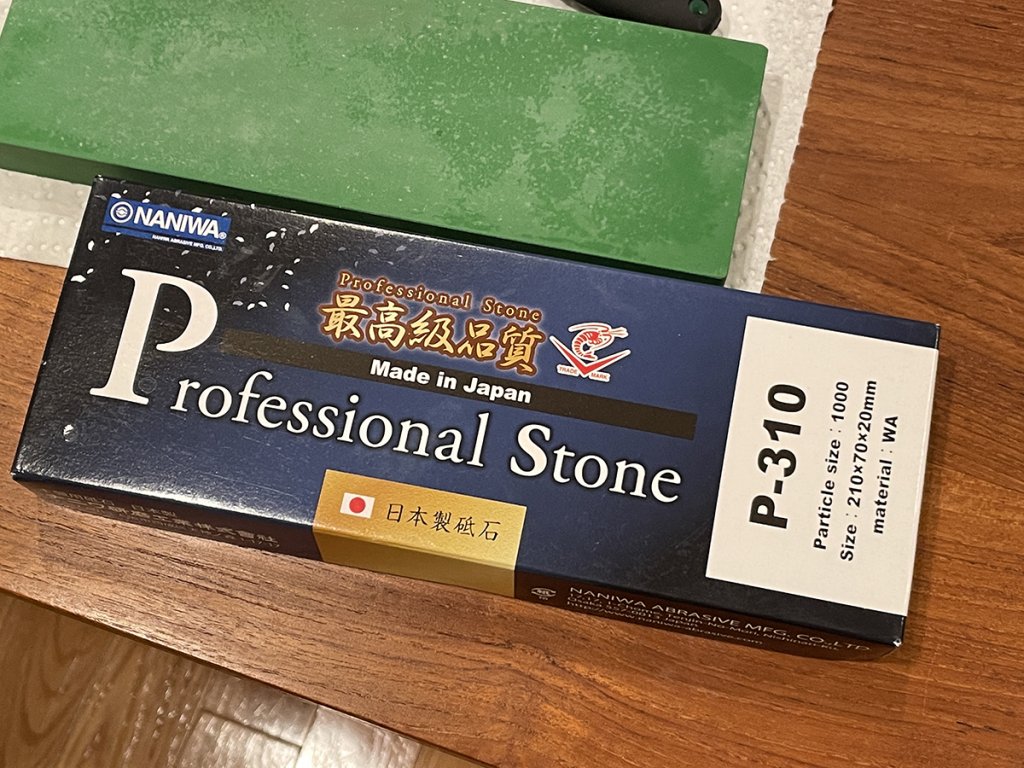

I emailed David to ask him if the center of the chip was lower then the rim, and he said it was, but only slightly. So I decided to use my 1000 grit wet stone (made for knife sharpening) to remove a small bit of material. This is a very fine grit, and the stone feels almost like glass -- This isn't rough and coarse like your typical sand paper you buy at your home improvement store.

I measured each chip with my calipers and made sure I got each chip down to 3.39mm (removing a little bit evenly from each side). Here is an example: This chip started at 3.45mm thick

Here is a video showing the method:

We are really only knocking off the high spots from the rim of the chip. The center doesn't get touched.

Here is the same chip after about 1-2 minutes of evenly removing material from each side

And here is the face of that same chip after sanding it from 3.45 to 3.38mm. The cross-hatching is still strong and looks great.

So after I did 20 chips down to at least 3.39mm, I washed the dust off and tested them in the rack. PERFECT! And looking at the face of the chips, you cant even tell they were sanded.

So the next thing I thought was, hmm, now these barrels of pumpkins will be slightly shorter than all the barrels of my 39mm. So I got a brand new barrel of my $500 39mm purple chips that have never been in play. To my surprise, they are the same height per barrel!

I wondered how that could be? So then I tried to put the barrel of purple into the oversized rack that the orange chips wouldn't fit into initially, and they fit great (not too tight at all). For some reason, I guess the 44mm chips are ever-so-slightly thicker than the 39mm chips, and modifying them like this makes them the exact same thickness as the 39mm chips.

Here is a barrel of un-modified brand new 39mm chips. They fit perfectly into the over-sized rack (width-wise).

So, a little before and after:

Here is a video showing trying to put stock CPC 44mm chips into the rack that don't fit:

Here is a video showing how nicely they go in after modifying them:

After searching online, and some back and forth with @David Spragg (and some members here), I learned that there aren't any chip racks on the market that will hold 44mm CPC chips. My only option is custom wood racks, or custom 3D-printed racks, neither of which I like the look of.

These generic chip racks are 67.87mm interior width.

And a barrel of CPC chips average about 68.26mm thick (too thick for the racks)

So after some thought and some math, I realized that these chips weren't too far off from fitting, and only a small amount would need to be removed from each chip for them to fit. With my calipers, I was averaging 3.41mm per chip from CPC, but they only needed to be down around 3.39mm to fit, so I would only need to remove .02mm on average (a human hair is about .06mm). The 3.41mm from the factory is "average" though. Some chips were below the 3.39mm already, and some of them were as high as 3.48 or even 3.52mm.

I emailed David to ask him if the center of the chip was lower then the rim, and he said it was, but only slightly. So I decided to use my 1000 grit wet stone (made for knife sharpening) to remove a small bit of material. This is a very fine grit, and the stone feels almost like glass -- This isn't rough and coarse like your typical sand paper you buy at your home improvement store.

I measured each chip with my calipers and made sure I got each chip down to 3.39mm (removing a little bit evenly from each side). Here is an example: This chip started at 3.45mm thick

Here is a video showing the method:

We are really only knocking off the high spots from the rim of the chip. The center doesn't get touched.

Here is the same chip after about 1-2 minutes of evenly removing material from each side

And here is the face of that same chip after sanding it from 3.45 to 3.38mm. The cross-hatching is still strong and looks great.

So after I did 20 chips down to at least 3.39mm, I washed the dust off and tested them in the rack. PERFECT! And looking at the face of the chips, you cant even tell they were sanded.

So the next thing I thought was, hmm, now these barrels of pumpkins will be slightly shorter than all the barrels of my 39mm. So I got a brand new barrel of my $500 39mm purple chips that have never been in play. To my surprise, they are the same height per barrel!

I wondered how that could be? So then I tried to put the barrel of purple into the oversized rack that the orange chips wouldn't fit into initially, and they fit great (not too tight at all). For some reason, I guess the 44mm chips are ever-so-slightly thicker than the 39mm chips, and modifying them like this makes them the exact same thickness as the 39mm chips.

Here is a barrel of un-modified brand new 39mm chips. They fit perfectly into the over-sized rack (width-wise).

So, a little before and after:

Here is a video showing trying to put stock CPC 44mm chips into the rack that don't fit:

Here is a video showing how nicely they go in after modifying them:

Last edited: