-

This site contains affiliate links. If you choose to make a purchase after clicking a link, Poker Chip Forum may receive a commission at no additional cost to you. Thank you for your support!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Poker Chip Milling For Labels (2 Viewers)

- Thread starter Tommy

- Start date

atomiktoaster

Full House

Router RPMs scare me on clay chips. I could duplicate that setup, but I'm hesitant to risk it.

luckbox

Straight

that is the best method that i have seen yet....someone needs to send that guy a rack or two of paulsons so he stops wasting time with the sluggos.....gear steal that idea, it seems it would produce a cleaner cut...thanks for that tommy

i think he needs to abandon his label process but maybe it works for him

i think he needs to abandon his label process but maybe it works for him

It actually seems kinda fun if you were doing it for your own chips under your own deadlines (with better chips and labels obviously).

If we are going to send him Paulsons, make sure they are post '90s. We don't want to inadvertently harm the guy you know.

If we are going to send him Paulsons, make sure they are post '90s. We don't want to inadvertently harm the guy you know.

Last edited:

atomiktoaster

Full House

It actually seems kinda fun if you were doing it for your own chips under your own deadlines (with better chips and labels obviously).

If we are going to send him Paulsons, make sure they are post '80s. We don't want to inadvertently harm the guy you know.

I thought the lead content was post 1996...? You're going to have much smaller dust with this method, much more likely to stay airborne.

That's not a bad way of doing it in terms of the finished product, but as noted it will create a lot of dust which could be bad if you're working with leaded chips.

I have a better method which I will be debuting VERY soon (I know, I have been saying that for a while) .... and of course, no glue stick required

I have a better method which I will be debuting VERY soon (I know, I have been saying that for a while) .... and of course, no glue stick required

Yup, I stand corrected.I thought the lead content was post 1996...? You're going to have much smaller dust with this method, much more likely to stay airborne.

luckbox

Straight

you beathe alot worse crap everyday....its not like your working in a factory doing this 12 hours a day, but yes maybe put a mask on....gear this means you. lol

i love the smell of leaded paulsons in the morning...there is a GIF around here but i am too lazy to look for it or create one..(y) :thumbsup:

i love the smell of leaded paulsons in the morning...there is a GIF around here but i am too lazy to look for it or create one..(y) :thumbsup:

Can't wait. I want to order a few thousand labels. The problem is the cost of shipping and milling to Canada. Was literally looking to buy a drill press today. I will wait till I hear this new method. If I can do it you will have one hell of a big label order incoming.I have a better method which I will be debuting VERY soon (I know, I have been saying that for a while) .... and of course, no glue stick required

Can't wait. I want to order a few thousand labels. The problem is the cost of shipping and milling to Canada. Was literally looking to buy a drill press today. I will wait till I hear this new method. If I can do it you will have one hell of a big label order incoming.

Here is a little teaser of what Gear is working on...

Updates?Here is a little teaser of what Gear is working on...View attachment 31182

ACE'S FULL

Pair

The latest update... He's made some custom tool purchases, and I haven't parked in the garage for a few weeks now. I can't say more, my back can't handle sleeping on the sofa.

However, I will quote Adam Savage. " The only difference between screwing around and science, is writing it down."

Gear has been writing down some learnings the past few weeks...

However, I will quote Adam Savage. " The only difference between screwing around and science, is writing it down."

Gear has been writing down some learnings the past few weeks...

Last edited:

Forty4

Full House

Interesting...

Pretty sure if my wife couldn't park in the garage at the end of February beginning of March, I would be the one sleeping on the couch.

Pretty sure if my wife couldn't park in the garage at the end of February beginning of March, I would be the one sleeping on the couch.

RainmanTrail

Straight Flush

This is pretty cool. The only caveat I see to this method is that if the chips aren't all exactly the same diameter, you're going to end up with different sized recesses. In most cases, this might not matter much, but if some of your chips are more worn than others, you may not be happy with the results.

The smaller the diameter of the chip, the wider the recess will be.

The smaller the diameter of the chip, the wider the recess will be.

Had to try milling with an actual router, no drill press, but seemed to work well. Actually makes for nice clean cuts on it's lowest setting, my only issue is that the bottom cleaning router bit doesn't leave a perfectly flat recess, the center is a little domed.Router RPMs scare me on clay chips. I could duplicate that setup, but I'm hesitant to risk it.

Very cool. Three questions. What is your setup for centering the chip? Did you eyeball the depth each time or have it preset? Explain your router setup. Thanks!Had to try milling with an actual router, no drill press, but seemed to work well. Actually makes for nice clean cuts on it's lowest setting, my only issue is that the bottom cleaning router bit doesn't leave a perfectly flat recess, the center is a little domed.

View attachment 79698

Had to try milling with an actual router, no drill press, but seemed to work well. Actually makes for nice clean cuts on it's lowest setting, my only issue is that the bottom cleaning router bit doesn't leave a perfectly flat recess, the center is a little domed.

View attachment 79698

Had the same issue. If you look at the bit, the cutting edge is not square. It's slightly concave, which in turn leaves you're work piece slightly convex or domed. Was planning on milling a bunch of chips myself, but have since abandoned the project after realizing I wouldn't be happy with the results.

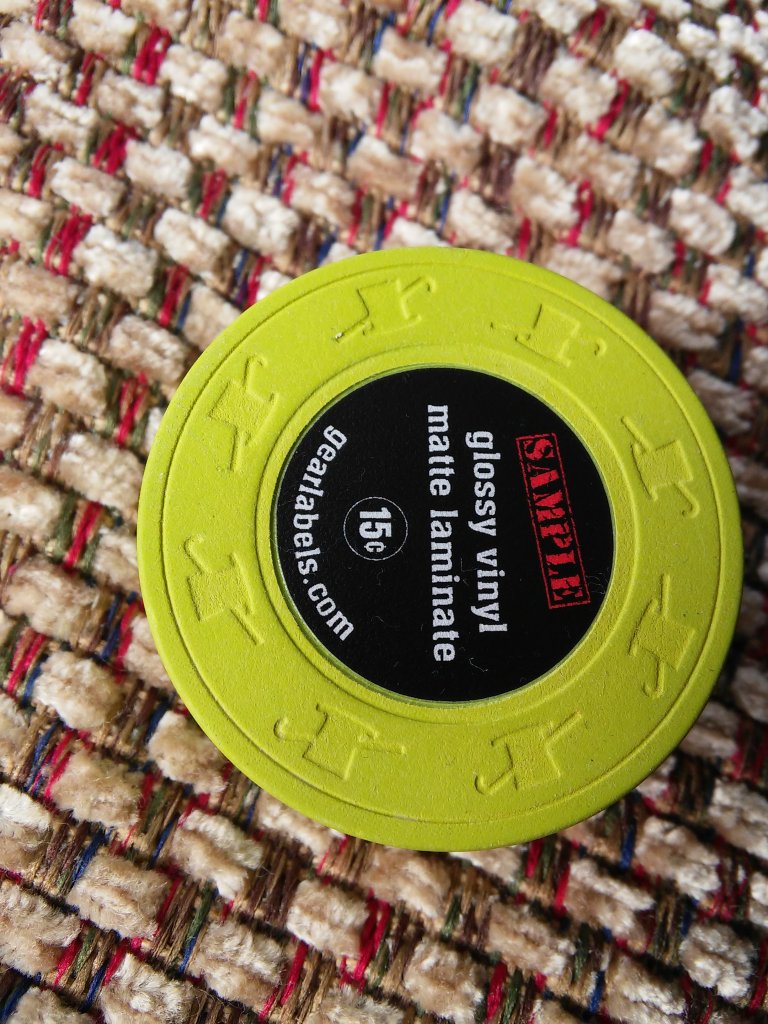

So I just got a new bit in the mail this morning and the difference was night and day. I was extremely happy with the results! I first bit I bought was branded 'uxcell'. While it was a nice sharp bit, the cutting edge was a bit too concave. The bit I got today branded 'magnate', had a much more square cutting edge. Though it is not truly square, it is much better than the

'uxcell' bit. I guess it really depends on what brand you get. Here are some pics with @Gear sample labels.

'uxcell' bit. I guess it really depends on what brand you get. Here are some pics with @Gear sample labels.

Last edited:

What size bit did you use for those? Looks bigger than 7/8ths.

What size bit did you use for those? Looks bigger than 7/8ths.

7/8. Got the bit on amazon. Here is the link. https://www.amazon.com/dp/B0093C1XKM/ref=sr_ph_1?ie=UTF8&qid=1486141450&sr=sr-1&keywords=magnets+7/8

If there is any wobble in the bit it will cut a fraction larger than 7/8". I believe that is why Gear went a different direction with his. If you get it set right and take all of the wobble out you should be fine with a consistent cut. Just watch the depth!What size bit did you use for those? Looks bigger than 7/8ths.

David O

I'm sure my drill press has a bit of wobble. It was very cheap. Just another tip...make sure the chip does not move when you are cutting. I mark my jig and then mark the chip with a pencil mark. I do this just in case it moves, so I can align it back up to prevent cutting an additional ridge in the chip.

Last edited:

Similar threads

- Locked

- Replies

- 35

- Views

- 2K

- Locked

- Replies

- 15

- Views

- 979