I'd like to put a query out to the table builders. I've stalled my table build until I can lock in the rail design and particularly where the playing surface stops & how the diffuser is mounted.

I was originally planning to keep the playing surface piece of plywood almost out to the edge for additional structure/rigidity, so when people lean on the rail there is no chance of any sag, but I've seen a few on PCF where the playing surface is its own piece that sits within the boundary of the rail and butts up against the diffuser. Therefore having the base as the only continuous piece of timber - it's possible that when I bolt the rail to the other surfaces, that this provides the desired rigidity anyway?

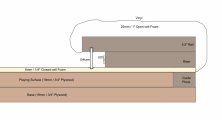

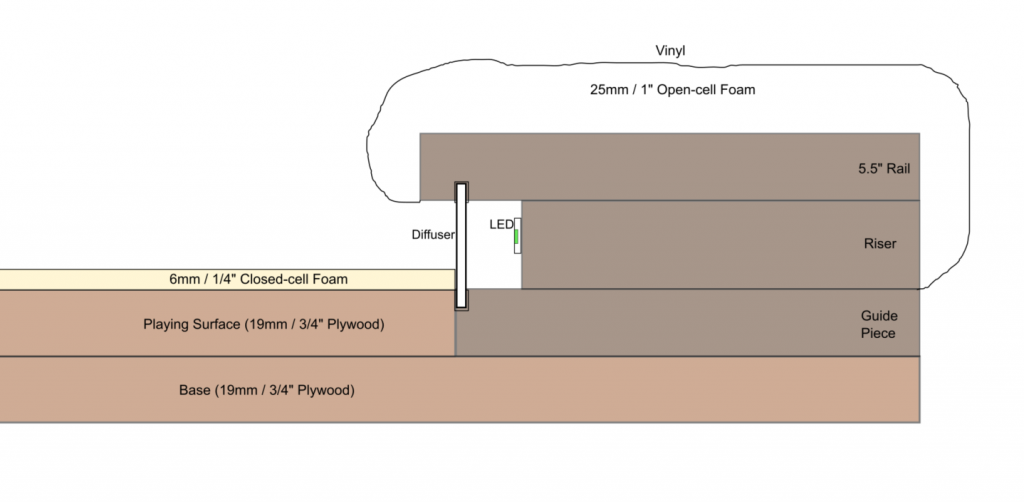

For simplicity, here's a few different design options:

Note: Darker brown colour shows pieces joined together for removable rail section.

Option 1 - Diffuser presses into foam/cloth (cloth stapled under riser or around playing surface)

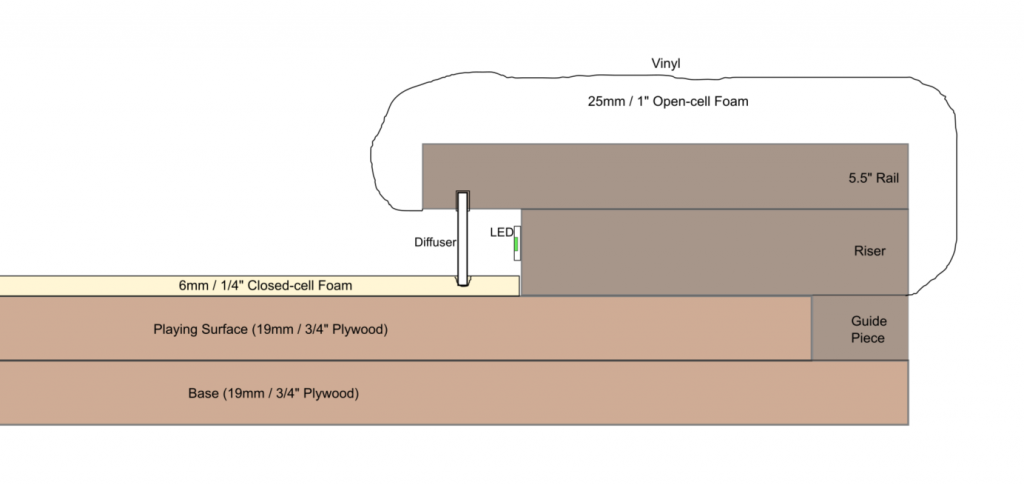

Option 2 - Playing surface padding runs to edge (riser compresses down on padding)

My concern with Options 1 and 2 is that this table will be assembled and disassembled between use, and I'm worried that the pressing on and off of the gaming cloth and padding may loosen or damage it over time.

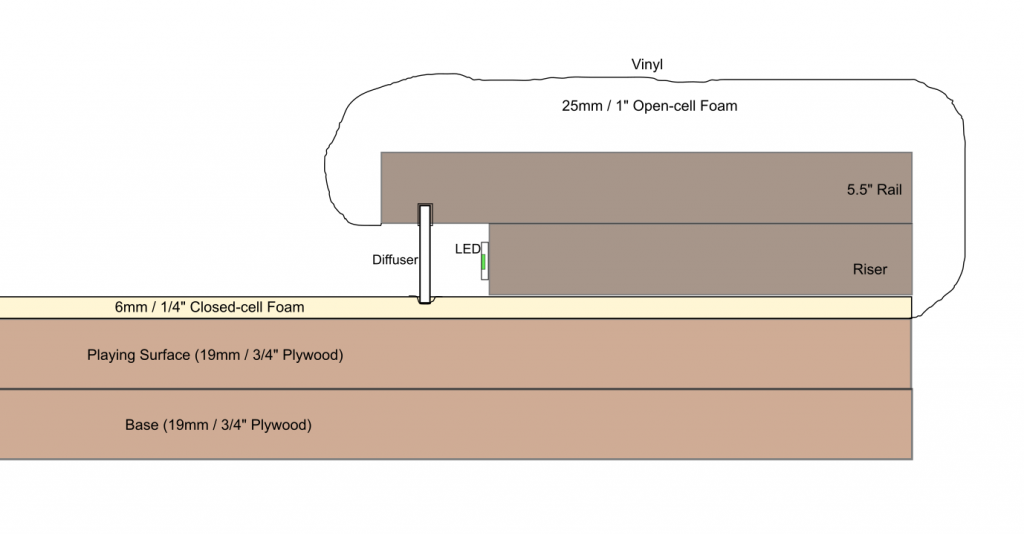

Option 3 - Cloth stapled on top, behind diffuser (similar to option 1, without pressing on padding)

note: gold is a cupholder, forgot to remove layer.

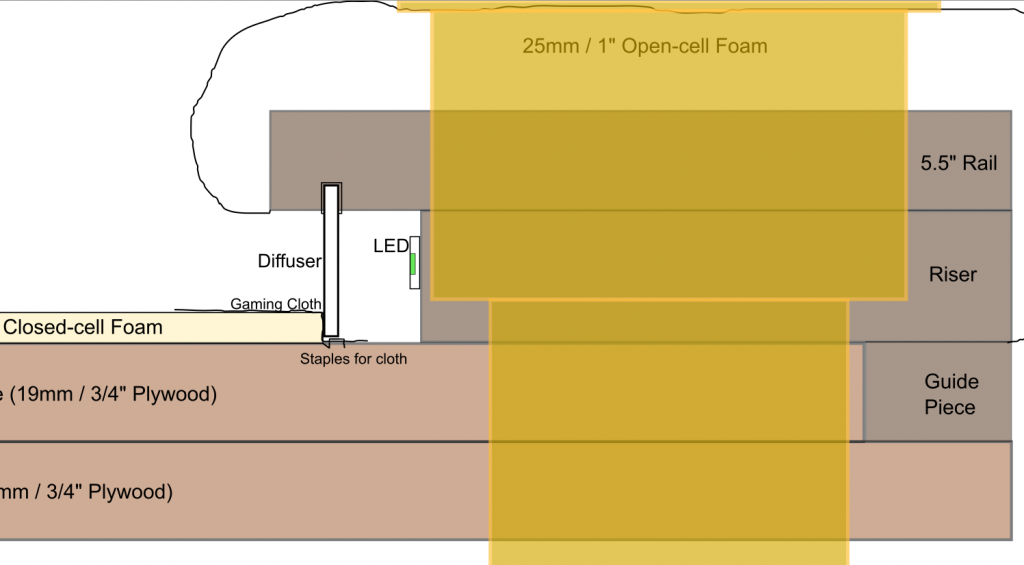

Option 4 - Playing surface is cut shorter, cloth wrapped around and stapled on underside (I think this is what I see a bit on PCF?)

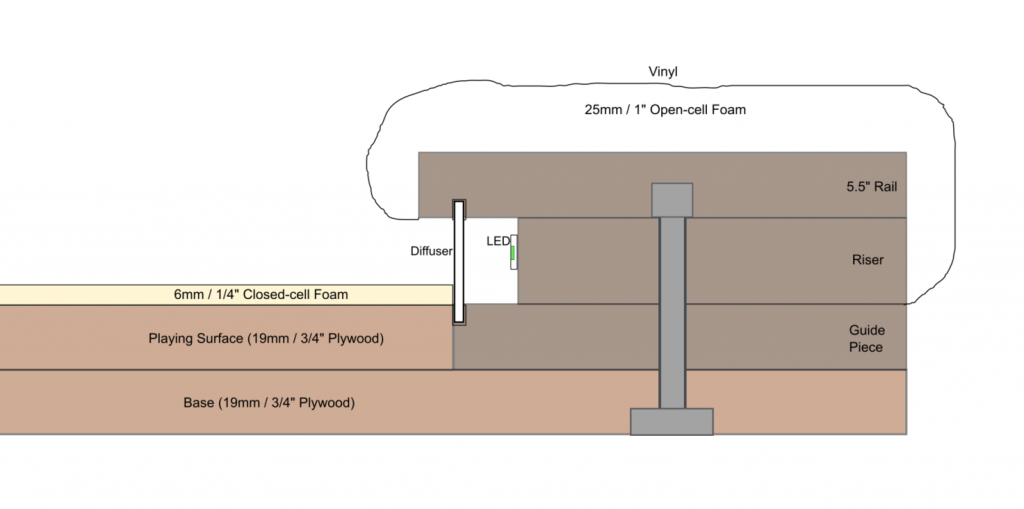

The graphic above shows my concern where weight on the rail is essentially taken by only the 1x 3/4" base piece, but then I'm guessing the playing surface pieces being snug up against each other and the whole thing bolted together provides some extra strength?

Here's one showing the considered bolt placement (about 6 or 8 around the table):

Any input on designs would be much appreciated, thank you!

I was originally planning to keep the playing surface piece of plywood almost out to the edge for additional structure/rigidity, so when people lean on the rail there is no chance of any sag, but I've seen a few on PCF where the playing surface is its own piece that sits within the boundary of the rail and butts up against the diffuser. Therefore having the base as the only continuous piece of timber - it's possible that when I bolt the rail to the other surfaces, that this provides the desired rigidity anyway?

For simplicity, here's a few different design options:

Note: Darker brown colour shows pieces joined together for removable rail section.

Option 1 - Diffuser presses into foam/cloth (cloth stapled under riser or around playing surface)

Option 2 - Playing surface padding runs to edge (riser compresses down on padding)

My concern with Options 1 and 2 is that this table will be assembled and disassembled between use, and I'm worried that the pressing on and off of the gaming cloth and padding may loosen or damage it over time.

Option 3 - Cloth stapled on top, behind diffuser (similar to option 1, without pressing on padding)

note: gold is a cupholder, forgot to remove layer.

Option 4 - Playing surface is cut shorter, cloth wrapped around and stapled on underside (I think this is what I see a bit on PCF?)

The graphic above shows my concern where weight on the rail is essentially taken by only the 1x 3/4" base piece, but then I'm guessing the playing surface pieces being snug up against each other and the whole thing bolted together provides some extra strength?

Here's one showing the considered bolt placement (about 6 or 8 around the table):

Any input on designs would be much appreciated, thank you!