You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Complete drill press milling setup tutorial with details and links (5 Viewers)

- Thread starter Eloe2000

- Start date

Eloe2000

Straight Flush

View attachment 762070

Finished my first chip. Made the mistake of not reading this all the way through and didnt get the Magnate bit so the chips are a little convex but have a magnate bit on the way now to get it sorted out

Awesome job! how convex did it turn out? I assume one of the common Amazon bits like Yonico or Excel?

Colquhoun

4 of a Kind

Beautiful!View attachment 762070

Finished my first chip. Made the mistake of not reading this all the way through and didnt get the Magnate bit so the chips are a little convex but have a magnate bit on the way now to get it sorted out

The Magnate bit is great, but it does leave behind a small amount in the very center, and if not removed, you'll feel it after the label is applied.

Before labeling, a small scrape with a sharp blade nicks that right off.

Thank you! It is definitely noticeable by sight and touch. The PDC label in the picture is thicker and textured so it hides it pretty good but I have some thinner labels that dont cover it at all. I'm fairly certain it was the yonico. They're still plenty usable and but it's just enough to drive me crazy so I'll give the magnate a shotAwesome job! how convex did it turn out? I assume one of the common Amazon bits like Yonico or Excel?

Thank you! I'll keep that in mind. I'm sure it wont be nearly as bad as the cheaper bit I'm using now.Beautiful!

The Magnate bit is great, but it does leave behind a small amount in the very center, and if not removed, you'll feel it after the label is applied.

Before labeling, a small scrape with a sharp blade nicks that right off.

And for anyone wanting to try this dont overthink it. I took a piece of probably 1/8" uhmw, pretty sure thats it, basically just plastic ran a 1.5" hole saw through it at the edge and wood screwed it to a piece of butcher block. I did have to tidy the cut up with sand paper but the chips fit really tight and I prefer to just eyeball each chip so it's not bolted down,to the drill press. It is a significant piece of butcher block so it doesnt move unless I make it move. Just give it a shot.

No hate on fancy precise jigs or safety measures if that's you're route go for it!

Interesting. Does this show up after the bit has been used for a while? I've done about 50 chips so far with my rig and the center of the chips is as smooth as any where else in the milled area.Beautiful!

The Magnate bit is great, but it does leave behind a small amount in the very center, and if not removed, you'll feel it after the label is applied.

Before labeling, a small scrape with a sharp blade nicks that right off.

Colquhoun

4 of a Kind

Mine left this tiny bump from day 1.Interesting. Does this show up after the bit has been used for a while? I've done about 50 chips so far with my rig and the center of the chips is as smooth as any where else in the milled area.

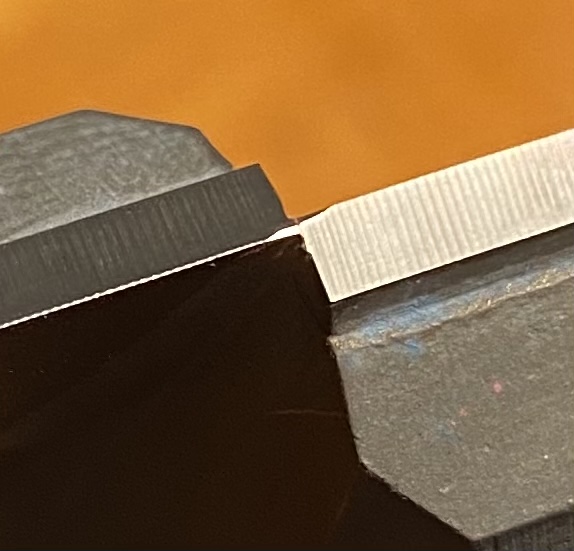

Here’s a couple photos:

Colquhoun

4 of a Kind

Dang, just put my Magnate bit under magnification, and the center, where the the two blades come together, there’s a small chamfered edge on both blades. It’s too perfect and identical on each blade to be by accident.

Maybe other Magnate bits are not always like this? Very interesting.

I figured it was that the blades just didn’t come together in the center...

If no one else’s bit is like this, congrats!

Maybe other Magnate bits are not always like this? Very interesting.

I figured it was that the blades just didn’t come together in the center...

If no one else’s bit is like this, congrats!

Last edited:

blindman

High Hand

Looking good. Did you get a Harbor Freight drill press.

RedRider52

Two Pair

I think I understand your issue, but I’m not sure what is depicted in the pic.Dang, just put my Magnate bit under magnification, and the center, where the the two blades come together, there’s a small chamfered edge on both blades. It’s too perfect and identical on each blade to be by accident.

Maybe other Magnate bits are not always like this? Very interesting.

View attachment 762194

I figured it was that the blades just didn’t come together in the center...

If no one else’s bit is like this, congrats!

Looking good. Did you get a Harbor Freight drill press.

Im not sure if you're talking to me, but no I have a larger drill press i've had for a while. I need to check what speed I was using but it seemed to work well and surface finish was great

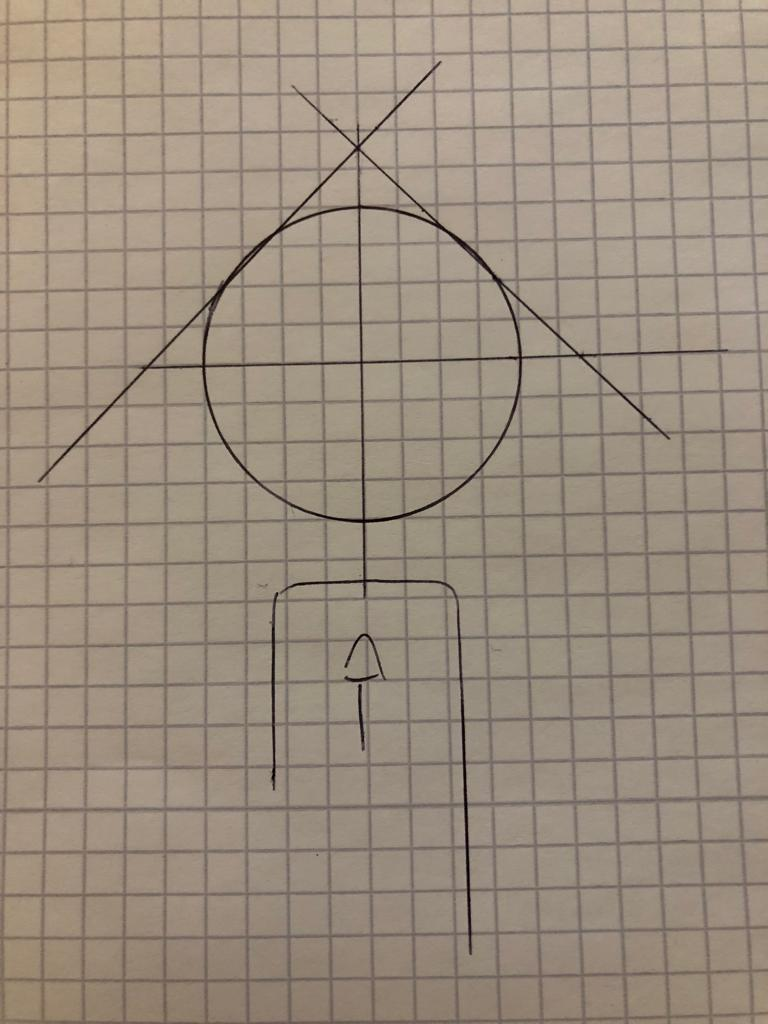

I'm currently building a milling rig myself and came up with the following design after reading through this thread.

Since @Eloe2000 mentioned, that one has to push the chip against the other side of the holding rig I thought to myself, why not just make a V cut into the wood and start pushing the chip in there straight up. Do you guys see any flaws with this idea?

FIY the rest is going to be the way Eloe proposed.

Picture for reference:

Since @Eloe2000 mentioned, that one has to push the chip against the other side of the holding rig I thought to myself, why not just make a V cut into the wood and start pushing the chip in there straight up. Do you guys see any flaws with this idea?

FIY the rest is going to be the way Eloe proposed.

Picture for reference:

Remember that not every chip is centered. Actually, most of them are off a chunk. Make sure that the jig itself can be mounted and moved easily to get the chip in the sweet spot.I'm currently building a milling rig myself and came up with the following design after reading through this thread.

Since @Eloe2000 mentioned, that one has to push the chip against the other side of the holding rig I thought to myself, why not just make a V cut into the wood and start pushing the chip in there straight up. Do you guys see any flaws with this idea?

FIY the rest is going to be the way Eloe proposed.

Picture for reference:

View attachment 840746

Eloe2000

Straight Flush

I'm currently building a milling rig myself and came up with the following design after reading through this thread.

Since @Eloe2000 mentioned, that one has to push the chip against the other side of the holding rig I thought to myself, why not just make a V cut into the wood and start pushing the chip in there straight up. Do you guys see any flaws with this idea?

FIY the rest is going to be the way Eloe proposed.

Picture for reference:

View attachment 840746

Other people have done this. I don't see any reason why not necessarily. Potentially there is more room for it to slip or pop out. But that is just a theoretical concern. Give it a shot.

I'm currently building a milling rig myself and came up with the following design after reading through this thread.

Since @Eloe2000 mentioned, that one has to push the chip against the other side of the holding rig I thought to myself, why not just make a V cut into the wood and start pushing the chip in there straight up. Do you guys see any flaws with this idea?

FIY the rest is going to be the way Eloe proposed.

Picture for reference:

View attachment 840746

Depending on how worn the chips are circumference-wise, the center of the chip will not always be in the same place and your milling will be off.

I bought one of these...

https://www.amazon.com/gp/product/B01MS1CL2H/ref=ppx_yo_dt_b_search_asin_image?ie=UTF8&psc=1

Allows me to easily and precisely adjust my jig.

Laser helps too

https://www.amazon.com/gp/product/B01MS1CL2H/ref=ppx_yo_dt_b_search_asin_image?ie=UTF8&psc=1

Allows me to easily and precisely adjust my jig.

Laser helps too

Eloe2000

Straight Flush

I'm currently building a milling rig myself and came up with the following design after reading through this thread.

Since @Eloe2000 mentioned, that one has to push the chip against the other side of the holding rig I thought to myself, why not just make a V cut into the wood and start pushing the chip in there straight up. Do you guys see any flaws with this idea?

FIY the rest is going to be the way Eloe proposed.

Picture for reference:

View attachment 840746

Actually, if I hadn't retired from milling, I had wanted to create some spring loaded (or tension loaded) mechanism to keep the chip into place. If you want to get crazy I would think about that problem for a minute. This would free up one of your hands.

Samuel

Straight

I wonder if something like this would work or could be made to work without too much effort?

https://www.esslinger.com/watch-tool-watch-case-holder/

https://www.esslinger.com/aluminum-watch-case-holder/

https://www.esslinger.com/case-vise-with-base-watch-holder/

https://www.esslinger.com/watch-tool-watch-case-holder/

https://www.esslinger.com/aluminum-watch-case-holder/

https://www.esslinger.com/case-vise-with-base-watch-holder/

I wonder if something like this would work or could be made to work without too much effort?

https://www.esslinger.com/watch-tool-watch-case-holder/

https://www.esslinger.com/aluminum-watch-case-holder/

https://www.esslinger.com/case-vise-with-base-watch-holder/

I basically use the same thing. I just changed out the plastic grommets. See pics above...

https://www.amazon.com/gp/product/B0753FKVMX/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Any ideas on how such a mechanism could look?Actually, if I hadn't retired from milling, I had wanted to create some spring loaded (or tension loaded) mechanism to keep the chip into place. If you want to get crazy I would think about that problem for a minute. This would free up one of your hands.

Samuel

Straight

I basically use the same thing. I just changed out the plastic grommets. See pics above...

https://www.amazon.com/gp/product/B0753FKVMX/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Nice! Sorry, I couldn't see it clearly - there I go trying to reinvent the wheel again! lol

CrazyEddie

Full House

I basically use the same thing. I just changed out the plastic grommets. See pics above...

https://www.amazon.com/gp/product/B0753FKVMX/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

... is there a big market for people who need a vice for carving walnuts?

Last edited:

View attachment 840847

View attachment 840848

... is there are big market for people who need a vice for carving walnuts?

apparently...

CrazyEddie

Full House

... okay, I'm not even gonna ask about "nuclear" then.

When I retire, I'll send you a PM. I have a mechanical jig and it's amazing.Actually, if I hadn't retired from milling, I had wanted to create some spring loaded (or tension loaded) mechanism to keep the chip into place. If you want to get crazy I would think about that problem for a minute. This would free up one of your hands.

Eloe2000

Straight Flush

Any ideas on how such a mechanism could look?

Honestly I hadn’t thought about it much. I would probably walk around Home Depot and try to find a sling mechanism I could retrofit for this purpose. Just realize you don’t need to apply a long of pressure and you also want to make it efficient with your time. I think some of the suggestions here will hold the chip rock solid in place but will take a fair amount of time to do and undo each time.

Also, my original jig worked but wore down a bit over time and the circle diameter widened. It still works without holding the chips for wider chips. And for narrower chips I could just buy a bit of tape inside to make the fit more snug so the chip doesn’t spin as well.

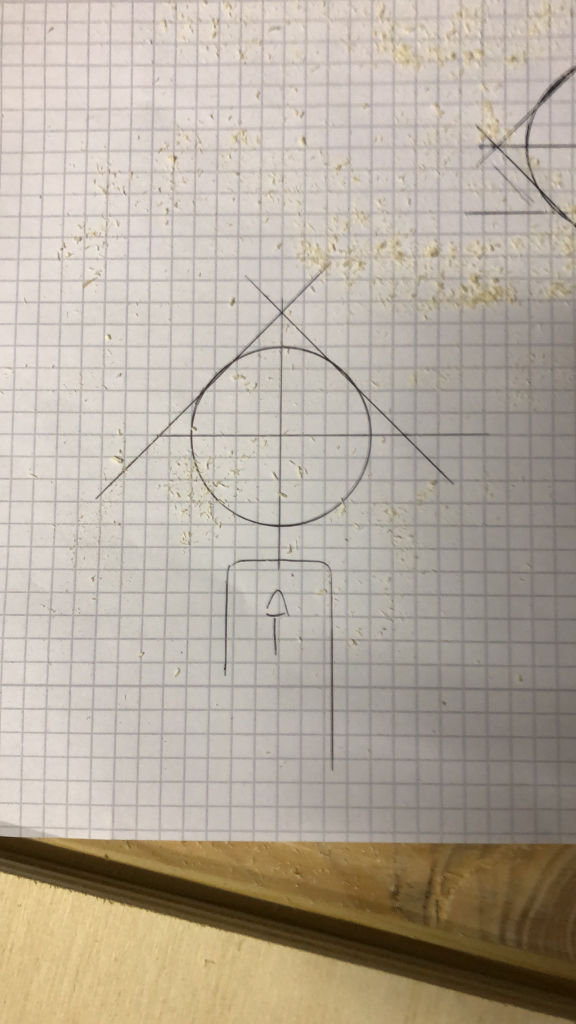

Ok, as promised, update time!!!

Today I wanted to cut out the V shape for the milling jig but before I even got started I realized that I didn't have the right tools for the job.... damn that's anticlimatic, sorry

Will give it another shot tomorrow with different tools.

Today I wanted to cut out the V shape for the milling jig but before I even got started I realized that I didn't have the right tools for the job.... damn that's anticlimatic, sorry

Will give it another shot tomorrow with different tools.

Ok, you know how life goes sometimes. The past week has just been busy af.

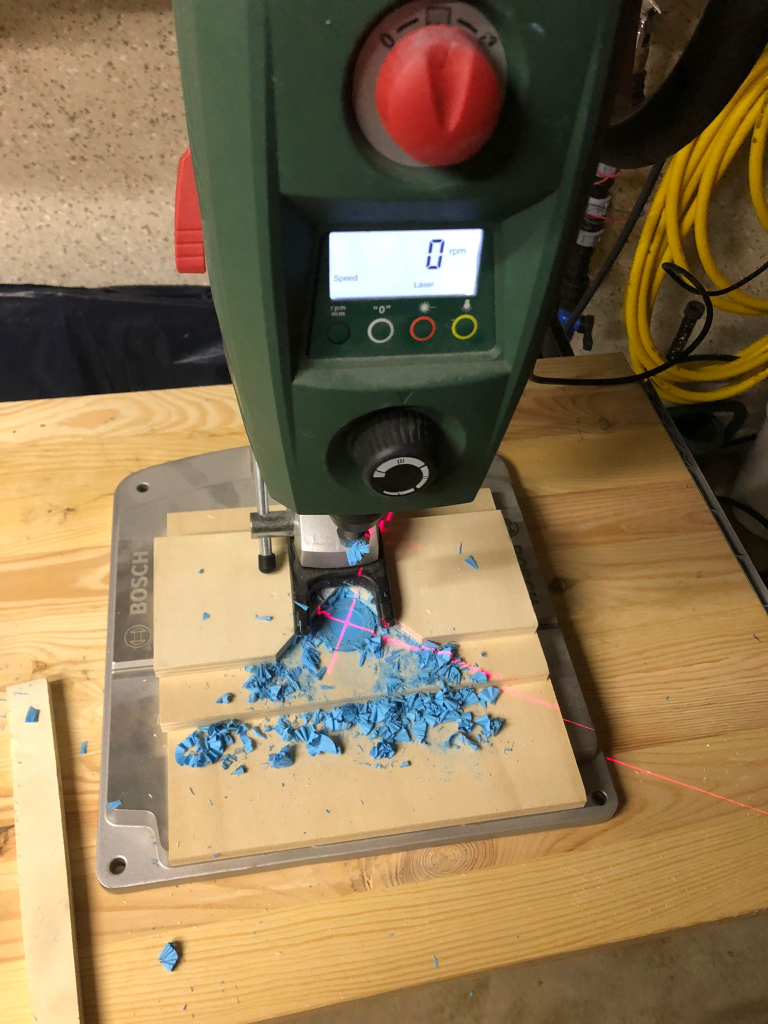

But good news are, today I managed to build everything.

So here goes my building pr0n and my experiences.

Please excuse all of the wanky a*s lines. I dont know what happened either xD

Here, the idea and the finished product. Although my lines where off af, this turned out quite nice!

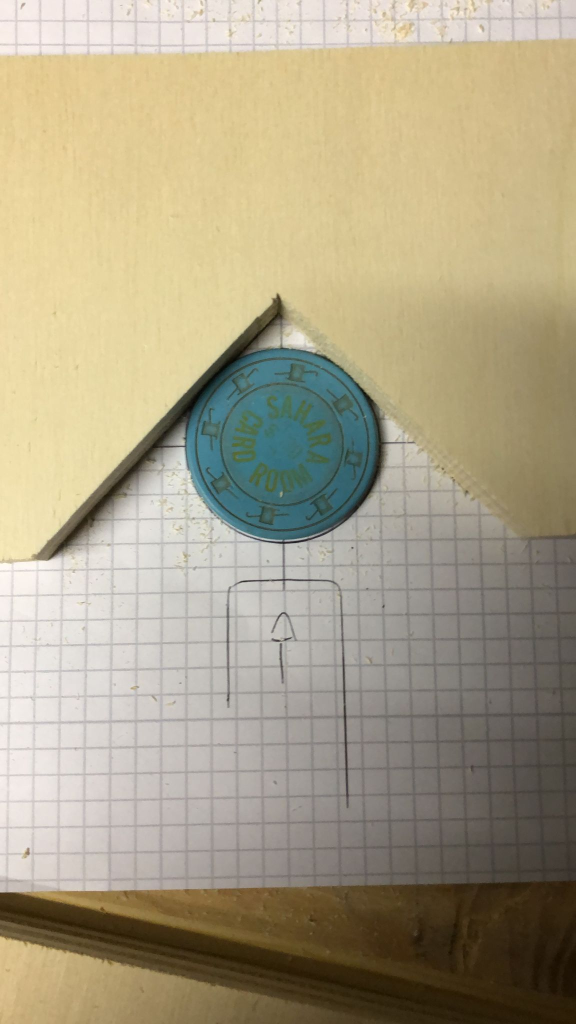

And here you can see my first try on the left and about three chips later another chip.

And now a picture of the chip in the milling jig:

So my experiences:

So I read on here that a slower speed is better but I can assure you, 200 rpm is waaaaaay to slow. I figured that about 650 rpm was more beneficial because I felt like the milling bit didn't catch that much on the chip. I However forgot to use a rubber mat underneath the chip so I had to jam the chip in there using a piece of wood wich was not optimal to say the least.

Tomorrow I will try it again with a piece of rubber.

The alignment was a bit of a pain but the laser from the drill press helped alot and also the videos from @Eloe2000.

So far I cannot find any obvious flaws with just cutting out a "V" shape. If you guys see anything that is improvement worthy, please tell me. I wont take it personally, I promise

But good news are, today I managed to build everything.

So here goes my building pr0n and my experiences.

Please excuse all of the wanky a*s lines. I dont know what happened either xD

Here, the idea and the finished product. Although my lines where off af, this turned out quite nice!

And here you can see my first try on the left and about three chips later another chip.

And now a picture of the chip in the milling jig:

So my experiences:

So I read on here that a slower speed is better but I can assure you, 200 rpm is waaaaaay to slow. I figured that about 650 rpm was more beneficial because I felt like the milling bit didn't catch that much on the chip. I However forgot to use a rubber mat underneath the chip so I had to jam the chip in there using a piece of wood wich was not optimal to say the least.

Tomorrow I will try it again with a piece of rubber.

The alignment was a bit of a pain but the laser from the drill press helped alot and also the videos from @Eloe2000.

So far I cannot find any obvious flaws with just cutting out a "V" shape. If you guys see anything that is improvement worthy, please tell me. I wont take it personally, I promise

Colquhoun

4 of a Kind

When you first started the plan for this, I was afraid the chip may spin within the V-shape, and it looks like this was the issue. The problem is that the chip is only held in place by 2 very small contact points in the back, plus the stick. If the jig is curved and more “chip-shaped”, it will contact more and may grab better.

Certainly, a pad on the bottom should help.

Maybe a thin strip of rubber glued to the inside of the V shape will give more grip and prevent spin?

Btw, one of my first milled chips looks exactly like the one on the left in your photo. I didn’t hold it tight enough and spun and wobbled within the jig. You learn quickly what NOT to do.

Certainly, a pad on the bottom should help.

Maybe a thin strip of rubber glued to the inside of the V shape will give more grip and prevent spin?

Btw, one of my first milled chips looks exactly like the one on the left in your photo. I didn’t hold it tight enough and spun and wobbled within the jig. You learn quickly what NOT to do.

louBdub

4 of a Kind

Ordered…. I just practiced and found out the non slip part is important

Hula Home Silicone Mat Sheet for Epoxy Crafts (15.7" x 11.7") Premium 1mm Thick Silicone Placemat for Liquid, Resin Sheet, Multipurpose Mat, Non-Stick No-Skid Heat-Resistant - Black https://www.amazon.com/dp/B09333NBHQ/ref=cm_sw_r_cp_api_i_QQR1NG7VXKVR14R4ESF3?_encoding=UTF8&psc=1

Hula Home Silicone Mat Sheet for Epoxy Crafts (15.7" x 11.7") Premium 1mm Thick Silicone Placemat for Liquid, Resin Sheet, Multipurpose Mat, Non-Stick No-Skid Heat-Resistant - Black https://www.amazon.com/dp/B09333NBHQ/ref=cm_sw_r_cp_api_i_QQR1NG7VXKVR14R4ESF3?_encoding=UTF8&psc=1

Similar threads

- Replies

- 35

- Views

- 2K

- Replies

- 43

- Views

- 3K