You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flattening chips - question (1 Viewer)

- Thread starter Goldfish

- Start date

FordPickup92

Royal Flush

What in tarnation

Maryland felt has been in play for well over 10 years......it had its time. Enter Animal House..... dawn of a new age (assuming I can figure out how to do this without ruining the felt)

Got mine today!

FordPickup92

Royal Flush

Lingenberry

Sitting Out

Was anxious about doing these for my chips but glad I found your all’s experience. Gonna practice this with my old chips first.

Don’t be surprised if u have to do some chips 2 or 3 times. Just keep at it. They will flatten......

OfficerLovejoy

Full House

They will indeed!

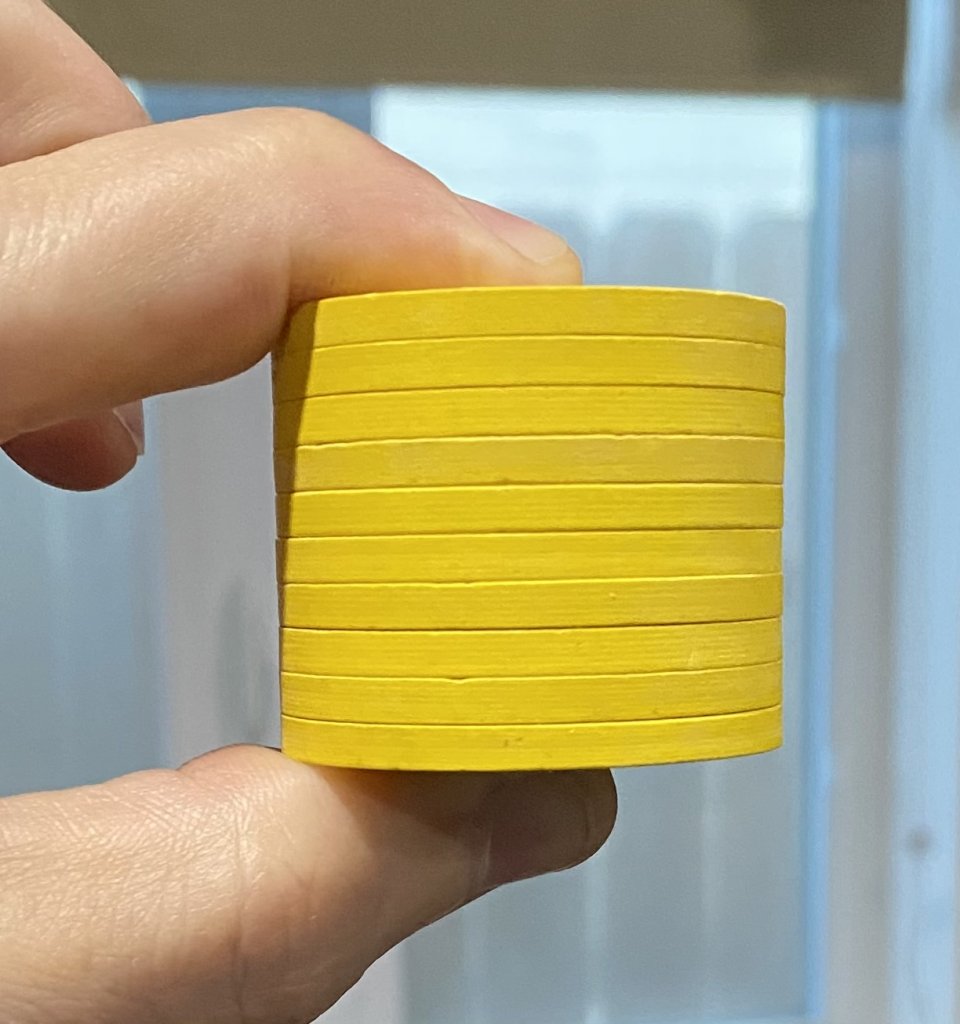

39mm ceramic blanks, 15 min at 50° celsius in an ordinary oven that allows such low degrees and letting cool in the clamps at room temperature (~1 hour) equals chips that finally stack like bricks.

39mm ceramic blanks, 15 min at 50° celsius in an ordinary oven that allows such low degrees and letting cool in the clamps at room temperature (~1 hour) equals chips that finally stack like bricks.

Skipracer

High Hand

I tried this but the Hat & cane seemed to almost disappear. Anyone else have this problem? I assumed I did it too tight, bit really didn’t think it was all that tight.

FordPickup92

Royal Flush

Either too much pressure, too hot, too much time in the heat, or all 3.I tried this but the Hat & cane seemed to almost disappear. Anyone else have this problem? I assumed I did it too tight, bit really didn’t think it was all that tight.

Did u use an oven or heating pad?I tried this but the Hat & cane seemed to almost disappear. Anyone else have this problem? I assumed I did it too tight, bit really didn’t think it was all that tight.

I tried this but the Hat & cane seemed to almost disappear. Anyone else have this problem? I assumed I did it too tight, bit really didn’t think it was all that tight.

Yikes! That doesn't sound good.

Colquhoun

4 of a Kind

Mild heat and just enough pressure to hold the group of chips together. Sounds like it may have been a little too much of both.I tried this but the Hat & cane seemed to almost disappear. Anyone else have this problem? I assumed I did it too tight, bit really didn’t think it was all that tight.

Best to start with less pressure than you think will work, you can always run it again if the chips still have a small warp.

Better to be safe...

- Joined

- Jul 12, 2020

- Messages

- 10,239

- Reaction score

- 15,927

got photos?I tried this but the Hat & cane seemed to almost disappear. Anyone else have this problem? I assumed I did it too tight, bit really didn’t think it was all that tight.

I am sure this question has been asked previously, but can you flatten hot stamp chips? Does the heat adversely affect the hot stamp? What do the experts say?

FordPickup92

Royal Flush

Yes you can, no it does notI am sure this question has been asked previously, but can you flatten hot stamp chips? Does the heat adversely affect the hot stamp? What do the experts say?

I am sure this question has been asked previously, but can you flatten hot stamp chips? Does the heat adversely affect the hot stamp? What do the experts say?

In my experience, it's the hot stamped chips that tend to be most warped in the first place.

Is there a link that shows the material and step by step process needed to flatten chips? Such as recommended vice grips, ceramic spacers, oven temp, time, etc? Also, when mentioning blank ceramics, are these the same as blank ceramic chips, say from Gene at ABC?

Thanks.

Thanks.

Last edited:

Colquhoun

4 of a Kind

post #9 in this thread, i describe the heating pad method. Although I used 39mm ceramic spacers, 43mm is recommended.Is there a link that shows the material and step by step process needed to flatten chips? Such as recommended vice grips, ceramic spacers, oven temp, time, etc? Also, when mentioning blank ceramics, are these the same as blank ceramic chips, say from Gene at ABC?

Thanks.

Yes, blank spacers from BRPro are the way to go.

To flatten chips you need:

1. Ceramic spacers (preferably 43 mm) from @BR Pro Poker. I would buy a full rack So you have plenty. They get dirty or messed up sometimes.

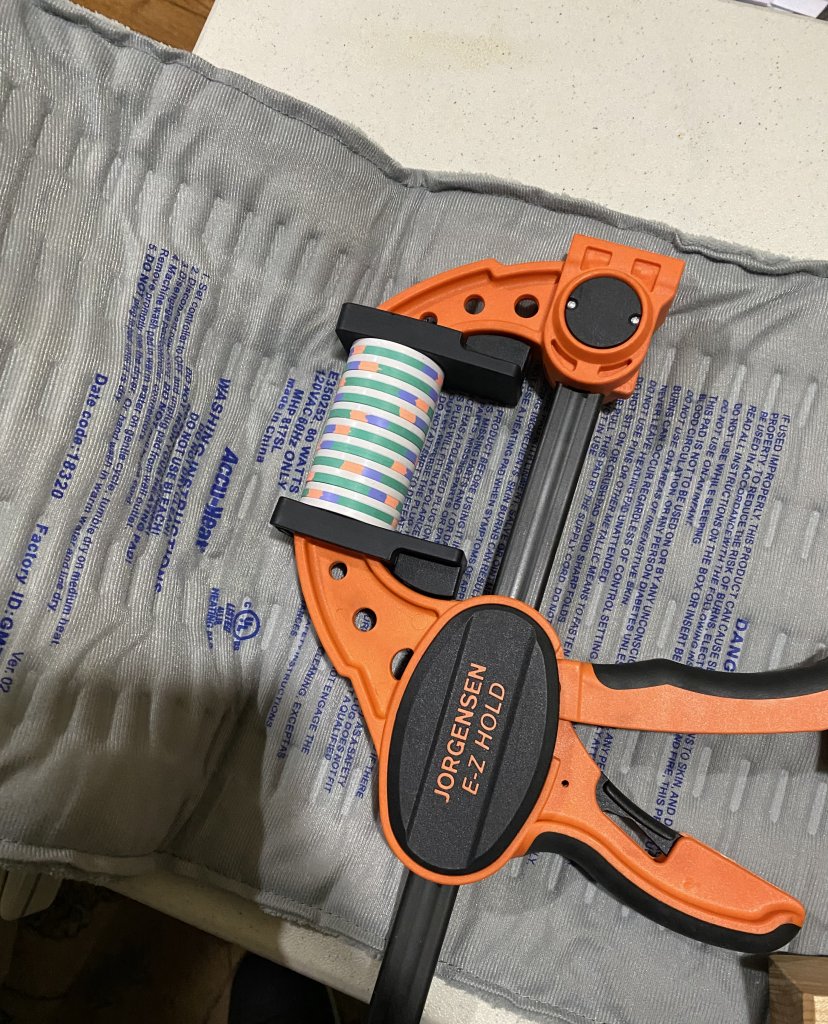

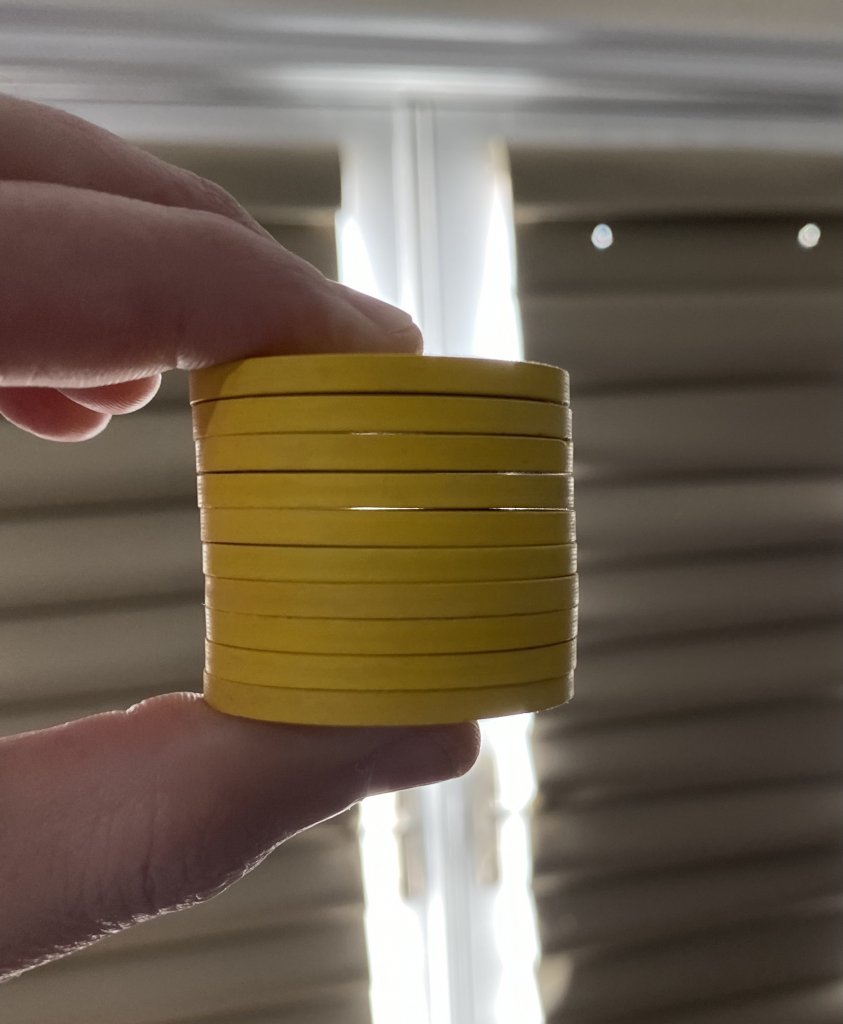

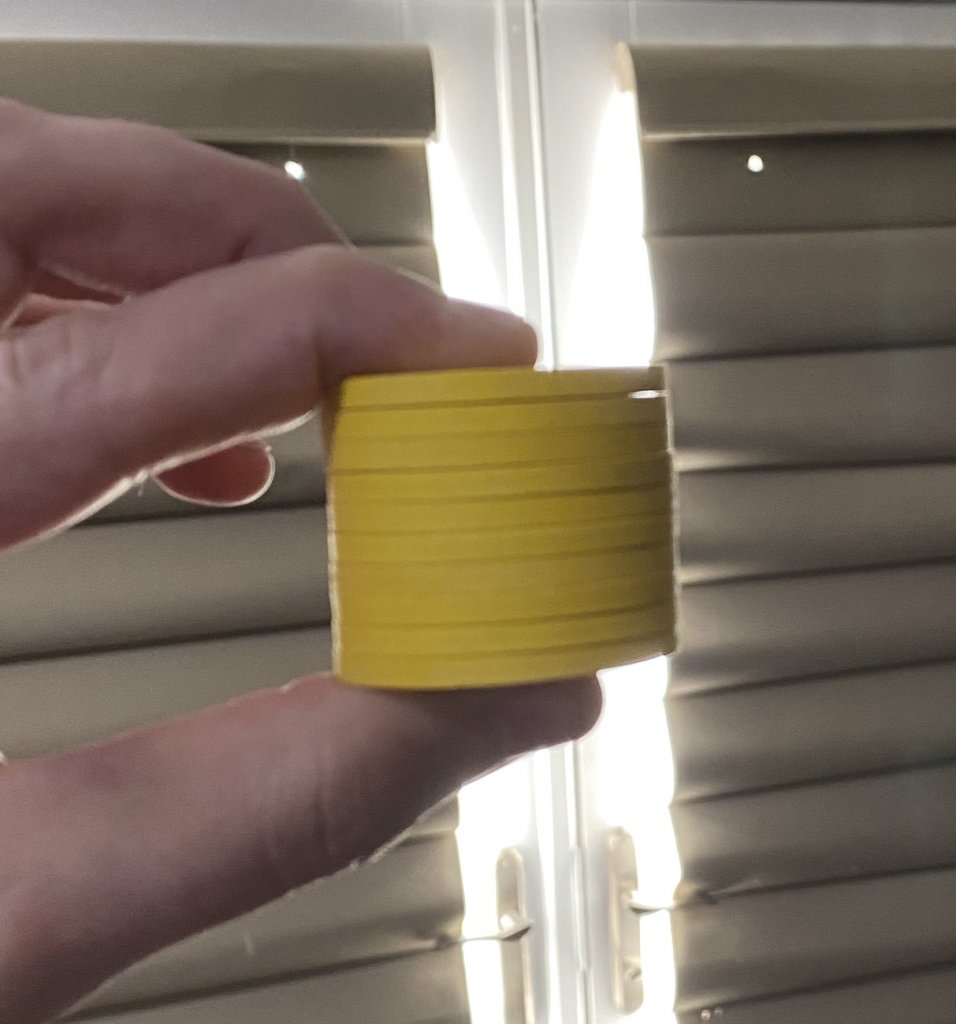

2. Clamps - see pic below. Each clamp holds 10 chips. I have 6 clamps.

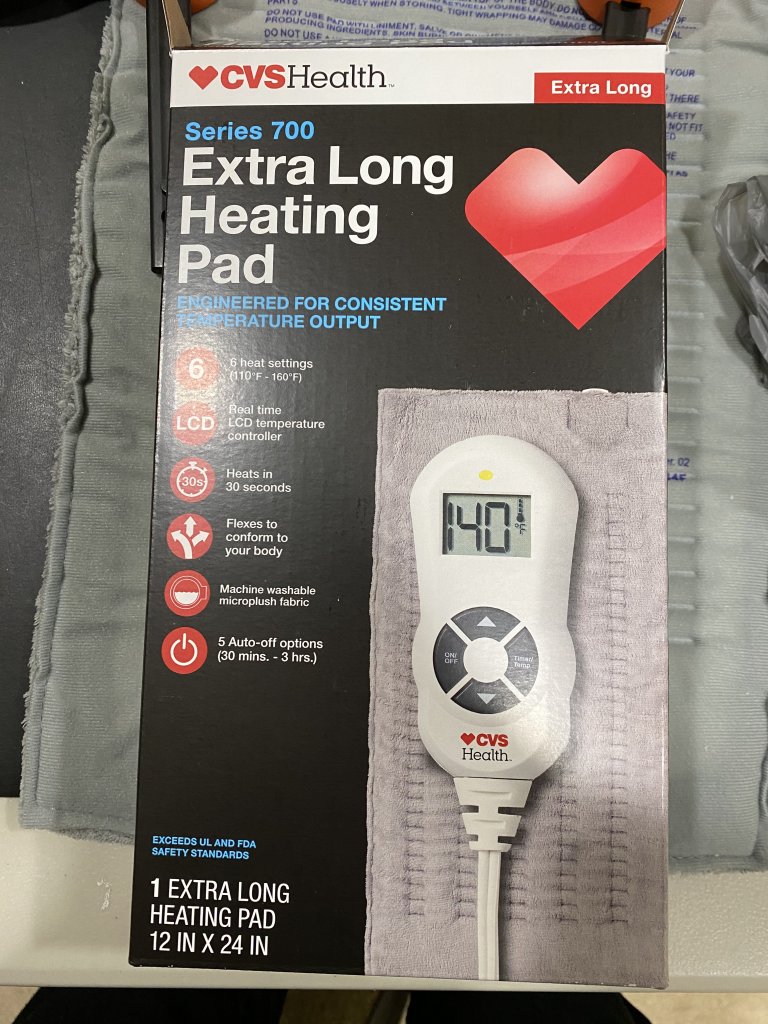

3. Heating pads. I have 3 hearing pads - see pic for type. I like this brand because it has a temp gauge and is extra long.

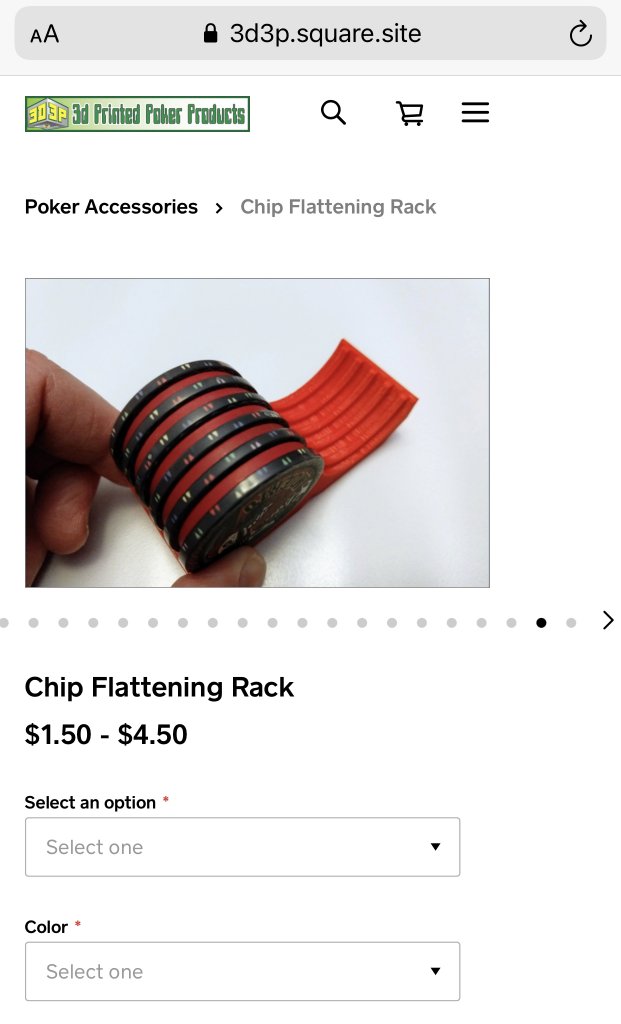

4. Ribbed chip holder which is necessary to stack the chips with the spacers and easily get them centered. Gets these from @One Eyed Dollar. See pick below.

5. infrared thermometer.

6. I heat the chips for 1 hour at 160 degree setting. Chips get to about 125-135 degrees. Let cool for at least 2 hours. Tighten the grips periodically while cooling. But not too tight.

1. Ceramic spacers (preferably 43 mm) from @BR Pro Poker. I would buy a full rack So you have plenty. They get dirty or messed up sometimes.

2. Clamps - see pic below. Each clamp holds 10 chips. I have 6 clamps.

3. Heating pads. I have 3 hearing pads - see pic for type. I like this brand because it has a temp gauge and is extra long.

4. Ribbed chip holder which is necessary to stack the chips with the spacers and easily get them centered. Gets these from @One Eyed Dollar. See pick below.

5. infrared thermometer.

6. I heat the chips for 1 hour at 160 degree setting. Chips get to about 125-135 degrees. Let cool for at least 2 hours. Tighten the grips periodically while cooling. But not too tight.

I just had my first experience with flattening warped chips. I’m happy with the results, so let me share...

Leaded THC hot stamps. Not horribly warped, but noticeable.

I used the heating pad method. Ceramic spacers. C-clamp. For first attempt, I set it to medium heat for 20 minutes (croc pot just for weight to hold down the heating pad). The clamp was only tight enough to hold the chips secure with no movement. When I took them out of the heating pad, I gave a slight tightening of the clamp, and left them to cool for another 20 minutes.

Improvement, but not perfect. Then I turned it up to the high heat setting, again for 20 minutes, removed from heat, slight tightening, and 20 minutes to cool.

Leaded THC hot stamps. Not horribly warped, but noticeable.

I used the heating pad method. Ceramic spacers. C-clamp. For first attempt, I set it to medium heat for 20 minutes (croc pot just for weight to hold down the heating pad). The clamp was only tight enough to hold the chips secure with no movement. When I took them out of the heating pad, I gave a slight tightening of the clamp, and left them to cool for another 20 minutes.

Improvement, but not perfect. Then I turned it up to the high heat setting, again for 20 minutes, removed from heat, slight tightening, and 20 minutes to cool.

Colquhoun

4 of a Kind

I don’t think 20 minutes is enough to heat them to the center when they’re in a barrel like that.

Alternatively, if you put 10 chips in the heating pad with no clamp, not touching each other, 10 minutes is plenty. Scoop them up, place spacers between, and clamp. You can do many more this way, and the heat gets all the way to the middle of each chip.

However, they need to cool completely while clamped. An hour would be the minimum I would wait to un-clamp.

Alternatively, if you put 10 chips in the heating pad with no clamp, not touching each other, 10 minutes is plenty. Scoop them up, place spacers between, and clamp. You can do many more this way, and the heat gets all the way to the middle of each chip.

However, they need to cool completely while clamped. An hour would be the minimum I would wait to un-clamp.

Mongoose

Full House

This is all great info. Thanks everyone!

I have several HS racks that need flattening.

heating pad = Check

Ceramic spacers = Check

Clamps = Check

43mm ribbed chip flattening rack = On order

I have several HS racks that need flattening.

heating pad = Check

Ceramic spacers = Check

Clamps = Check

43mm ribbed chip flattening rack = On order

How about laying the ceramics flat in the heating pad too? Might as well keep heat on the spacers.Alternatively, if you put 10 chips in the heating pad with no clamp, not touching each other, 10 minutes is plenty. Scoop them up, place spacers between, and clamp.

Nanook

Full House

Thanks for the know how...I don’t think 20 minutes is enough to heat them to the center when they’re in a barrel like that.

Alternatively, if you put 10 chips in the heating pad with no clamp, not touching each other, 10 minutes is plenty. Scoop them up, place spacers between, and clamp. You can do many more this way, and the heat gets all the way to the middle of each chip.

However, they need to cool completely while clamped. An hour would be the minimum I would wait to un-clamp.

I just clamped up my first 10 + 11 ceramics. I bought the CVS extra long heating pad with the digital temp control. I laid them all out on the heating pad, set the heating pad to 140°F and let them sit for 10 min. I don't have anything to measure how hot the chips got, but I don't think that is really necessary. It looks like I can easily heat up a barrel of chips + a barrel of blanks at a time and by cutting about 6" of 1.5" PVC pipe in half it makes lining everything up a snap. I have all sorts of the quick clamps so I should be able to breeze through a rack quickly. I am using 39mm ceramics and I will check to make sure there is no damage to the chips after everything cools off before I go into high volume mode. I will post pics before, during and after once I am confident that my method is solid.

Nanook

Full House

Seems like it would likely work, but then you have the mess of the water to clean up or at least dry off the chips. Lots of us, including me have cleaned many chips water with no harm. I'm guessing you could throw a bunch of chips in water @ 120°F ish and all the chips would heat through in probably a minute or less as water is an excellent conductor of heat. Clamp them up just like I did and let them sit. Probably work great without the cost of a heating pad.Is wetting the chips ever recommended? Or will that lead to problems?

Nanook

Full House

They came out great!

I used 39 mm ceramics that I had laying around. I have blanks on order, but it looks like any random ceramics will do. Looking at the chips under high magnification, post flattening I see no evidence whatsoever that the 39mm blanks left any sort of ridge or flattened out any of the cross hatching so I am sticking to the 39 mm ceramics vs 43 which seems to me would be tough to line up without some sort of device like the 43mm ribbed chip flattening rack. That seems unnecessary to me... whatever works, right?

I used 39 mm ceramics that I had laying around. I have blanks on order, but it looks like any random ceramics will do. Looking at the chips under high magnification, post flattening I see no evidence whatsoever that the 39mm blanks left any sort of ridge or flattened out any of the cross hatching so I am sticking to the 39 mm ceramics vs 43 which seems to me would be tough to line up without some sort of device like the 43mm ribbed chip flattening rack. That seems unnecessary to me... whatever works, right?

Colquhoun

4 of a Kind

I had originally considered hot water before finally discovering a heating pad.

The problem with water is:

The problem with water is:

- it's hard to know what the temperature is.

- it cools as the chips soak

- too much time (cooling) between lightly drying and clamping

- can only be done in a wet-friendly environment

Good point. Anyone have a sous vide they can test it out in?I had originally considered hot water before finally discovering a heating pad.

The problem with water is:

- it's hard to know what the temperature is.

- it cools as the chips soak

- too much time (cooling) between lightly drying and clamping

- can only be done in a wet-friendly environment

Similar threads

- Locked

Ends 11-10-24 at 7:30 PM Eastern Time

- Replies

- 4

- Views

- 344

- Locked

Ends 11-10-24 at 7:00 PM Eastern Time

- Replies

- 7

- Views

- 409

- Replies

- 37

- Views

- 2K