You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Milling Pr0n w/ g0re (4 Viewers)

- Thread starter Ethan

- Start date

Gah! Not just murder, but mutilation!

BillyBluff

Flush

DOH. Hopefully, no digits were lost in the process and everyone is OK?!

NotRealNameNoSir

4 of a Kind

Hey big homies, looking for answers in this beautiful thread. So if I buy hotstamped clay chips, they can be milled so that the top layer is stripped away, no hotstamp left? Ive seen some beautiful solid chips with stamps I don't like and I was unsure whether this was the answer.

Thanks for any time given.

Thanks for any time given.

Lots of great resources out there on this. Short answer - yes. There is a big facet of this hobby dedicated to repurposing chips. Here is a DYI resource thread. Note, it takes real time a patience to do it right.Hey big homies, looking for answers in this beautiful thread. So if I buy hotstamped clay chips, they can be milled so that the top layer is stripped away, no hotstamp left? Ive seen some beautiful solid chips with stamps I don't like and I was unsure whether this was the answer.

Thanks for any time given.

https://www.pokerchipforum.com/thre...-setup-tutorial-with-details-and-links.55889/

Otherwise, there are OGs like @Josh Kifer who do the hard work for you at a very reasonable price. Lots of people put their trust in him with great results. Check out his vendor page here: https://www.pokerchipforum.com/forums/kifer-milling-co.105/

Happy chipping!

NotRealNameNoSir

4 of a Kind

Thank you very much for the leads and links, noted. Ill study up.Lots of great resources out there on this. Short answer - yes. There is a big facet of this hobby dedicated to repurposing chips. Here is a DYI resource thread. Note, it takes real time a patience to do it right.

https://www.pokerchipforum.com/thre...-setup-tutorial-with-details-and-links.55889/

Otherwise, there are OGs like @Josh Kifer who do the hard work for you at a very reasonable price. Lots of people put their trust in him with great results. Check out his vendor page here: https://www.pokerchipforum.com/forums/kifer-milling-co.105/

Happy chipping!

RocAFella1

Royal Flush

dmoney

Full House

Had to do a quick test. Milling is far superior to an exacto knife for paper inlay removal.

What machines do yall recommend for milling? Looks fun lol

I ended up buying a Harbor Frieght drill press on sale a couple years ago for only $53. It needed a little adjusting to get it proper, but it was a helluva deal. I only wanted it to do a few hundred chips. If you plan on doing more, I recommend a higher level press.What machines do yall recommend for milling? Looks fun lol

More important is the bit. Magnate makes great clean-out bits.

Dope I can look into drill press and find something cheap, just looking to do some simple projects for myself. Thanks for the infoI ended up buying a Harbor Frieght drill press on sale a couple years ago for only $53. It needed a little adjusting to get it proper, but it was a helluva deal. I only wanted it to do a few hundred chips. If you plan on doing more, I recommend a higher level press.

More important is the bit. Magnate makes great clean-out bits.

dmoney

Full House

Trying to chip away at about 1,200 chips, averaging about 10 mins per barrel

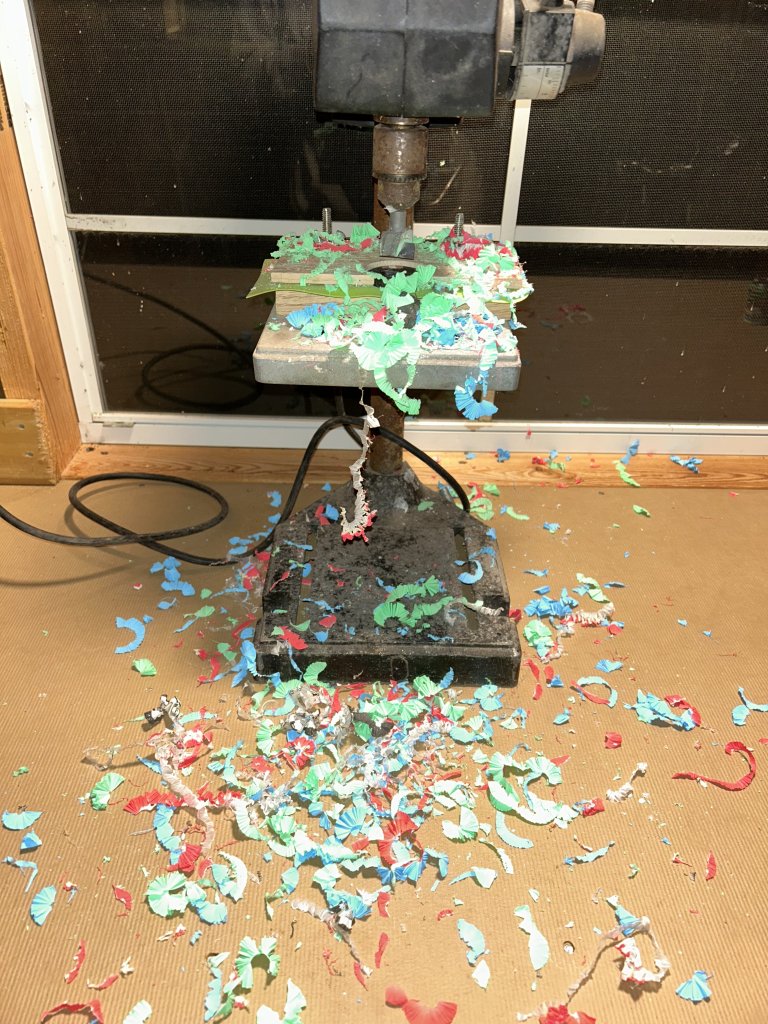

Nice view!View attachment 1252679

Trying to chip away at about 1,200 chips, averaging about 10 mins per barrel

Go slow, and be careful to not mill too deep…usually no deeper than the hats and canes.

dmoney

Full House

I have some chips with an inlay that are being removed, and I only go as deep as the current inlay. I’m mixing in barrels of hotstamp chips to keep it consistent (vs all inlays then all hotstamps, where I might forget how deep to go)Nice view!

Go slow, and be careful to not mill too deep…usually no deeper than the hats and canes.

dmoney

Full House

~*sings*~ Nightmilling deserves a quiet night

Dingdingding

Two Pair

View attachment 1250984

Had to do a quick test. Milling is far superior to an exacto knife for paper inlay removal.

Sterling 100s are actually the only chips i removed the inlays from so far, but i was thinking these would be vinyl

dmoney

Full House

I think I’ve been corrected - these are vinyl but in my experience did not come out cleanly at all. I find milling to be a better option.Sterling 100s are actually the only chips i removed the inlays from so far, but i was thinking these would be vinyl

dmoney

Full House

loosechange

High Hand

mcfilthy

High Hand

Beautiful shavings

First set down!!

It’s milling time!!

It’s milling time!!

mburnznj

3 of a Kind

Reminds me of when I was a kid and I use the hand held pencil sharpener on some Crayola colored pencils.

Fun times....

Moxie Mike

Full House

So what's the final frontier of chip revival? Crosshatch restoration?

I have been considering this! Something like a wide, course file…heat up chips and clamp.So what's the final frontier of chip revival? Crosshatch restoration?

One can dream.

Moxie Mike

Full House

I imagine the crosshatch texturing is part of the mold although it's possible it's something that's added after the compression process while the clay is still plyable.I have been considering this! Something like a wide, course file…heat up chips and clamp.

One can dream.

From ChatGTP:

- Molding and Casting: For more advanced restoration, you could create a mold of one of the better-preserved chips (if available) and use it as a guide to recast the texture onto the worn chips. This involves applying a small amount of resin to the chip's surface and pressing the mold onto it to imprint the texture.

- Laser Engraving: If you have access to more sophisticated equipment, laser engraving can be used to precisely etch the crosshatch pattern back onto the chips. This method offers a high degree of control and can produce results very close to the original texture.

Yes, the cross-hatch is part of the original pressing…I just thought for some of the more worn chips where the hatching is gone, maybe a clamping to a hatched surface with a similar texture while the chip was heated would help recreate the hatch on the chip.I imagine the crosshatch texturing is part of the mold although it's possible it's something that's added after the compression process while the clay is still plyable.

From ChatGTP:

- Molding and Casting: For more advanced restoration, you could create a mold of one of the better-preserved chips (if available) and use it as a guide to recast the texture onto the worn chips. This involves applying a small amount of resin to the chip's surface and pressing the mold onto it to imprint the texture.

- Laser Engraving: If you have access to more sophisticated equipment, laser engraving can be used to precisely etch the crosshatch pattern back onto the chips. This method offers a high degree of control and can produce results very close to the original texture.

Similar threads

- Replies

- 0

- Views

- 421

- Replies

- 7

- Views

- 564

- Replies

- 10

- Views

- 497

- Replies

- 7

- Views

- 409