Next level would be a moldThx!

You’ve got to be 1/3 crazy, 1/3 chipnized, 1/3 DIY guy to do such things like a dealer button…

but i can live with - no choice… ; )

Pls show your epoxy results when it‘s done. Sounds interesting!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dealer button (DIY) (1 Viewer)

- Thread starter SwissChip

- Start date

This was my initial question here on PCF, if anyone did a mold himself. ; )Next level would be a mold

It requires a 3D printer, then cast a silicone mold.

Or the Lambo version: CNC-cut metal plates.

I have a Cutter and sandpaper…

He didThis was my initial question here on PCF, if anyone did a mold himself. ; )

It requires a 3D printer, then cast a silicone mold.

Or the Lambo version: CNC-cut metal plates.

I have a Cutter and sandpaper…

https://www.pokerchipforum.com/threads/strasser-clay-chips.54500/

Stuff showed up early. Guess I know what I'm doing this weekend.This was my initial question here on PCF, if anyone did a mold himself. ; )

It requires a 3D printer, then cast a silicone mold.

Or the Lambo version: CNC-cut metal plates.

I have a Cutter and sandpaper…

80oz of silicone mold maker was part of the order. Planning on trying epoxy versions of a lot of my 3d prints.

Thx Santa!

Dude got a real press!! And the right clay it seems.

But it looks a bit sloppy, or are the pics wobbly?

In progress… ; )

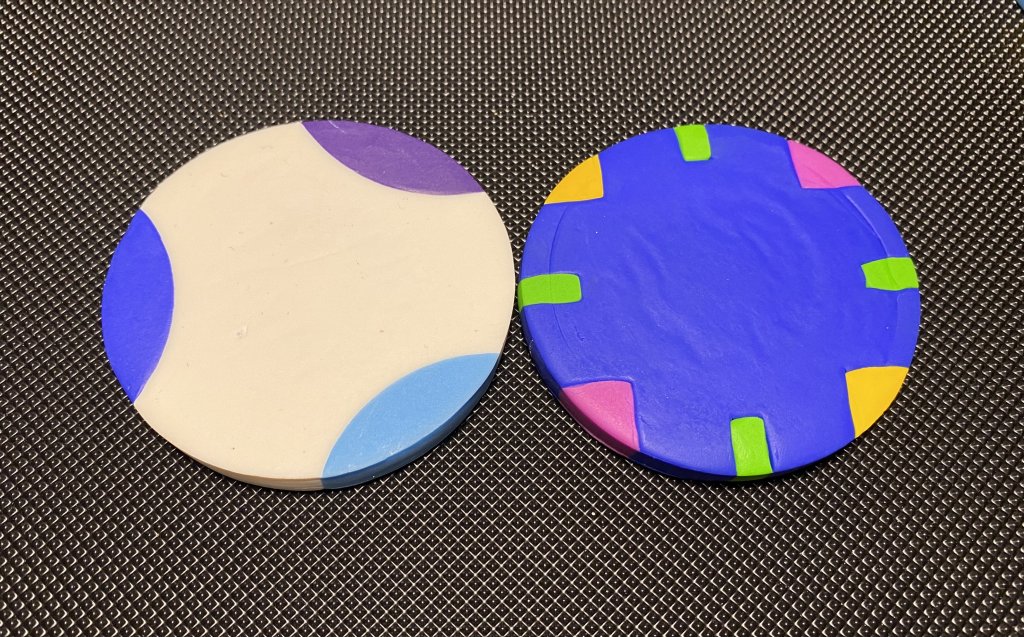

Some 58/7mm, 42g Ds

These are all a bit fancy, maybe i do some more oldschool classic.

Still waiting for labels fit on the 68mm…

I guess i‘ll do a small giveaway when these are done.

These are all a bit fancy, maybe i do some more oldschool classic.

Still waiting for labels fit on the 68mm…

I guess i‘ll do a small giveaway when these are done.

ekricket

Royal Flush

Can you put a 39mm chip in the insert in the button? So you can change it out for each game?Can you put a normal 39mm Chip next to the buttons

Dude.

Sweet.

I’m going to hobby lobby asap.

Sweet.

I’m going to hobby lobby asap.

Hmmm… this would be MUCH easier 3D printed - but a good idea.Can you put a 39mm chip in the insert in the button? So you can change it out for each game?

tBuOK

Sitting Out

Amazing!! Great work!

Some want to get them banned from the table, some do their own ; )

Still a couple more to finish - had to do a Tiger 500 approach, but not enough colors to get near to orchid, so it‘s blue : )

Still a couple more to finish - had to do a Tiger 500 approach, but not enough colors to get near to orchid, so it‘s blue : )

batterytime

Waiting List

I've thought about 3d printing a chip before but making it out of clay is really cool!

And it‘s not difficult - if you don‘t have 2 left hands, it‘s doable.I've thought about 3d printing a chip before but making it out of clay is really cool!

The ‚circus‘ V8 will be a giveaway.

Got some clay left and now a ‚pentamoon‘ is in the oven ; )

I absolutely love this pattern!

How do you make the recess for the label?I absolutely love this pattern!

View attachment 1324064View attachment 1324065View attachment 1324066

No recess - i can‘t milling…; )

A thin laminated label on top. Easy to replace if worn or damaged.

Clear you can feel the label on top, but it‘s not made to be shuffled or stacked during the game.

It needs some tools to make a ‚real’ chip/button, that i don‘t have.

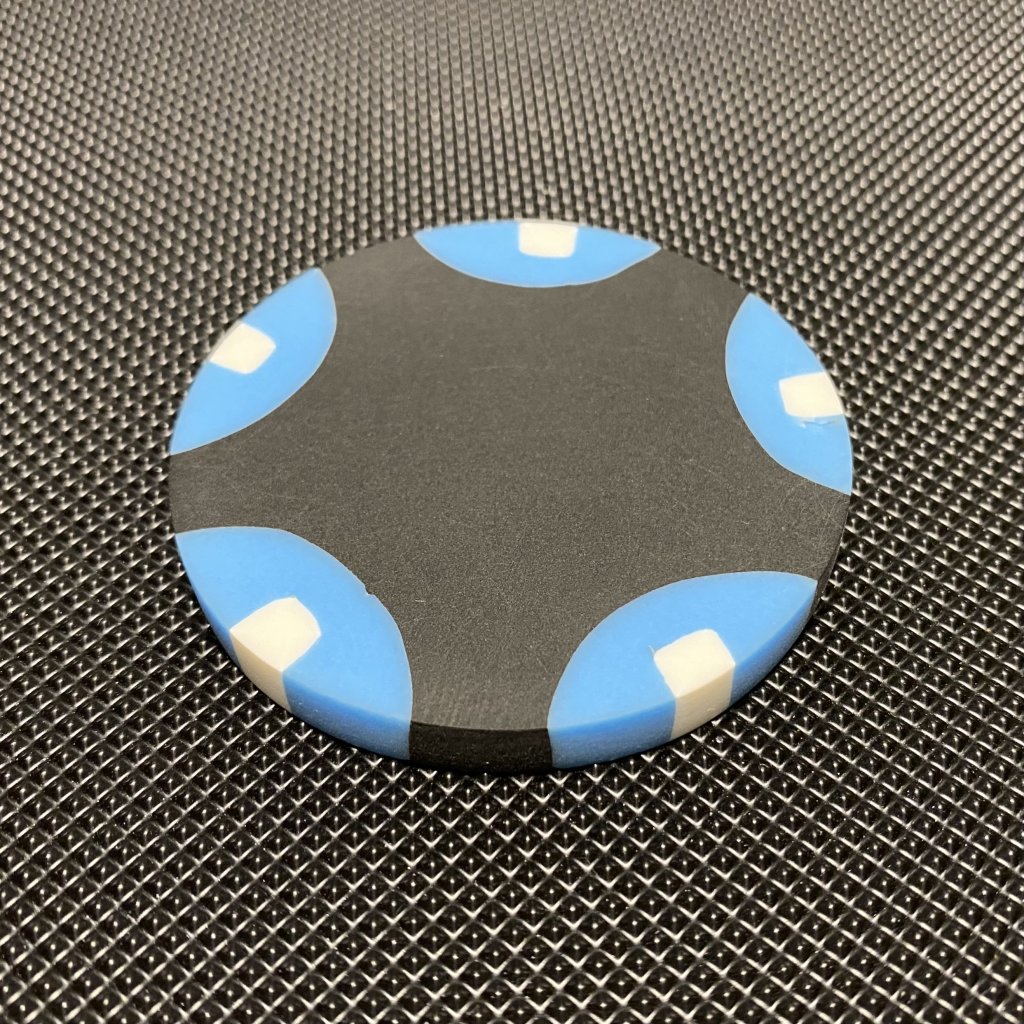

This one is ‚bridge size‘ 57/6mm 38g

A thin laminated label on top. Easy to replace if worn or damaged.

Clear you can feel the label on top, but it‘s not made to be shuffled or stacked during the game.

It needs some tools to make a ‚real’ chip/button, that i don‘t have.

This one is ‚bridge size‘ 57/6mm 38g

Thanks. Cant you press by your hand in the soft clay a recess before putting the clay into the oven? Just an idea. Don't know if it is worth it.No recess - i can‘t milling…; )

A thin laminated label on top. Easy to replace if worn or damaged.

Clear you can feel the label on top, but it‘s not made to be shuffled or stacked during the game.

It needs some tools to make a ‚real’ chip/button, that i don‘t have.

This one is ‚bridge size‘ 57/6mm 38g

View attachment 1324074

Yes i thought about it and placed once a coin (magnet actually) before baking.

The problem is i sand them down to get smooth and it‘s impossible to sand 100% straight by hand. Even milling afterwards would be the same issue.

Only a compressing mold and/or a sanding machine would do the job precise enough…

The problem is i sand them down to get smooth and it‘s impossible to sand 100% straight by hand. Even milling afterwards would be the same issue.

Only a compressing mold and/or a sanding machine would do the job precise enough…

As one DIYer to another, well done! These are great. How did you get the pucks so perfectly round and flat? And the inserts? I assumed you had used a mold, until I read the post where you said you did not.

I love the Simon Says button. All of them, actually! Maybe you can document your next one step by step for anyone who wants to give this a try?

Thanks!These are awesome! Amazing colors as well. Kinda want a 600 chip set made out of these.

Well the colors are great. The weight too with a washer inside. But it‘s more like plastic than clay when it‘s cured.

The real clay would be fantastic!!

Thanks, appreciate that!

As one DIYer to another, well done! These are great. How did you get the pucks so perfectly round and flat? And the inserts? I assumed you had used a mold, until I read the post where you said you did not.

I love the Simon Says button. All of them, actually! Maybe you can document your next one step by step for anyone who wants to give this a try?

I sand them down to size with 80/120/240/600 grid.

Yes i can do a more detail how-to, got some clay left. It‘s very simple, just time consuming so i prefer do this during winter time…

The real clay would be fantastic!!

Psst! I have a secret recipe. The additives and amounts are self-explanatory:

Ok i cut all my t-shirts in fibres, grind a fishing sinker + a vinyl record. Got some titanium line guides. And a baryte under my bed.

But no color pigments ; )

But no color pigments ; )

ekricket

Royal Flush

Do you guys dye Easter eggs over there?Ok i cut all my t-shirts in fibres, grind a fishing sinker + a vinyl record. Got some titanium line guides. And a baryte under my bed.

But no color pigments ; )

Yes - not me, but yes. Mostly with onion skin.

This is what you need for (+ oven of course)Maybe you can document your next one step by step for anyone who wants to give this a try?

Not sure if i do one more next week. But if i‘ll take some pics.

I have a diode laser and am wondering if anyone has tried engraving polymer clay. I’ve done some googling and can’t find anything specific.

The alternative is that I can cut a stamp that could be pressed into the clay to make the mold patterns.

I bought some fimo last year for my daughter to make some Christmas ornaments for my wife but I can’t find it anywhere… maybe I just have to buy some…

The alternative is that I can cut a stamp that could be pressed into the clay to make the mold patterns.

I bought some fimo last year for my daughter to make some Christmas ornaments for my wife but I can’t find it anywhere… maybe I just have to buy some…

Similar threads

- Replies

- 4

- Views

- 139

- Poll

- Replies

- 11

- Views

- 511

- Replies

- 12

- Views

- 613

- Replies

- 37

- Views

- 2K