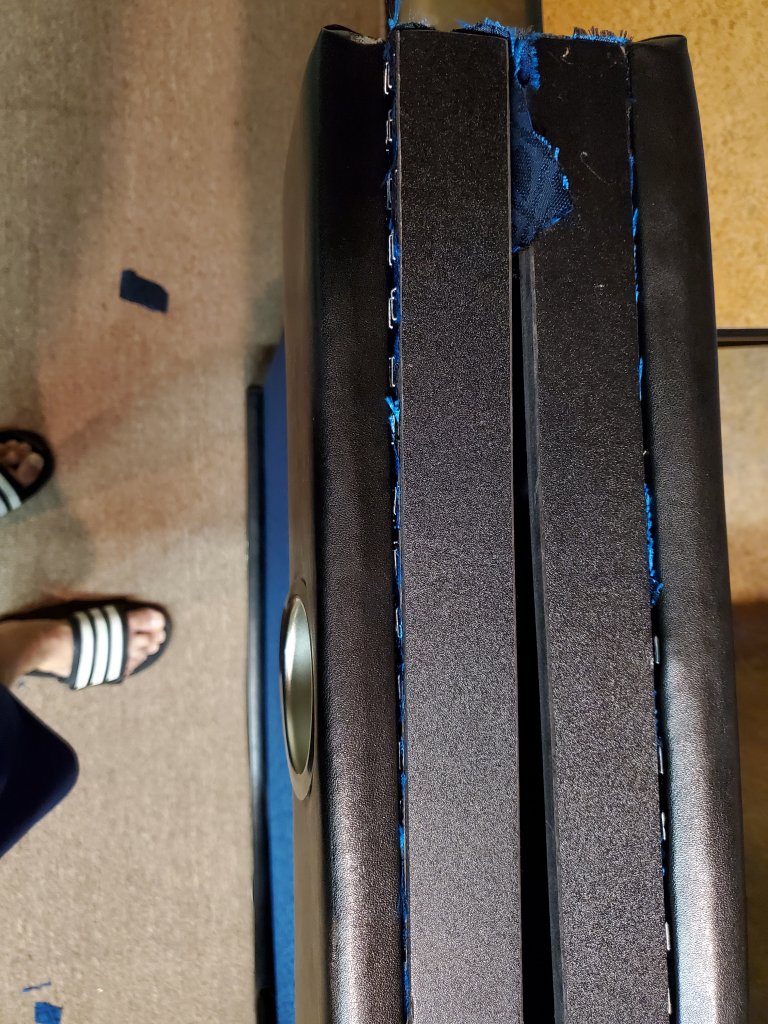

Anyone know of a good cover to protect this while it's folded up, especially in transport?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barrington poker table thread (81 Viewers)

- Thread starter SixSpeedFury

- Start date

Forty4

Full House

Back down to $180 still not $100 but better than the $230 they were the past few weeks.

pbraves

Sitting Out

I’m on the cusp of buying one now, tired of waiting. One thing I’m questioning is how comfortable the arm rests are — they look super boxy, sharp, and stiff. Can anyone comment on how it feels playing for 3+ hours?

If you're a heavy arm rester you'll definitely start to feel it but you'll manageable. I'd always advise going for a lightly used non-folding table from facebook marketplace/offerup/letgo etc. You can usually get something awesome for $300-$400 - so about double a Barrington. Granted most people inevitably invest another $30-$150 in fixing up into Barrington tables for new felt/hinge/handles/deep cupholders etc etc etc.I’m on the cusp of buying one now, tired of waiting. One thing I’m questioning is how comfortable the arm rests are — they look super boxy, sharp, and stiff. Can anyone comment on how it feels playing for 3+ hours?

If you don't have the room though and need a folding table then they're your best and practically only option.

Forty4

Full House

I picked mine up last night and even though I only “spent” $50 on mine as I had gift cards, I will say I was a little disappointed. I’ll try to take pictures this weekend but visible staples on the underside of the rail, poorly inserted screws, poor rail padding, poor wrapping job on the rail.

Now if I was getting this for sub $100 I would expect those things but the current price of $180 I just want to let everyone know what to expect. I think money could be spent in better ways. I got this as a travel table and not sure how long it will actually hold up to travel before something happens.

We will also see how it goes when I redo the gaming surface.

Now if I was getting this for sub $100 I would expect those things but the current price of $180 I just want to let everyone know what to expect. I think money could be spent in better ways. I got this as a travel table and not sure how long it will actually hold up to travel before something happens.

We will also see how it goes when I redo the gaming surface.

Altheman003

3 of a Kind

After contemplating for a while I finally picked up one these tables. Had the wife give me a hand to take it apart and throw some new speed cloth on. I went with the reverse platinum and it really upgraded the look of the table big time. I got it all back together but my issue is that it doesn’t seem as stable in the center of the table. You guys think it’s the hinges? Legs? I tried my best putting everything back exactly how they were. Any help to solve this issue without taking everything completely apart again would be appreciated.

Only progress shot I took till I get a game together

Thanks

-Alen

Only progress shot I took till I get a game together

Thanks

-Alen

1A25R

Flush

Anyone tried to dim the original LED lights of the ESPN Barrington table? I found that they are too bright, therefore unusable...

not me but a couple here had and said the sameAnyone tried to dim the original LED lights of the ESPN Barrington table? I found that they are too bright, therefore unusable...

1A25R

Flush

wondering if such kind of dimmer can make the trick

https://www.amazon.com/Controller-V...rDC12-24V-Conjunction-sync-work/dp/B071S7Q42Z

https://www.amazon.com/Controller-V...rDC12-24V-Conjunction-sync-work/dp/B071S7Q42Z

TonZaga

Straight

Went through the speed cloth swap out on the Barrington this afternoon. PSA: pay attention as to what side of the speed cloth will be showing!  . I was in such a rush to get it back together that I think one of the halves cloth is upside down. Either side is 10000x better than that shitty felt. Hopefully none of my buddies notice it or I'm sure I'll never live it down lol.

. I was in such a rush to get it back together that I think one of the halves cloth is upside down. Either side is 10000x better than that shitty felt. Hopefully none of my buddies notice it or I'm sure I'll never live it down lol.

Attachments

SixSpeedFury

Full House

For those who did custom felts, how did you get the image centered so perfectly if you have to cut the felt in half?

Moxie Mike

Full House

For those who did custom felts, how did you get the image centered so perfectly if you have to cut the felt in half?

The suited speed felt is pretty forgiving as far as the pattern goes. As long as you don't put it on crooked, it isn't difficult to get the pattern reasonably close when you go to reupholster the second half.

If I recall, I think I used spring clamps to hold the felt in place on the curved end as I stretched and lined it up with the other half, then I stapled it. The felt wraps around the edge of the playing surface and there's a slight gap between the two halves so it's not like it needs to match up perfectly to look decent.

SixSpeedFury

Full House

The suited speed felt is pretty forgiving as far as the pattern goes. As long as you don't put it on crooked, it isn't difficult to get the pattern reasonably close when you go to reupholster the second half.

If I recall, I think I used spring clamps to hold the felt in place on the curved end as I stretched and lined it up with the other half, then I stapled it. The felt wraps around the edge of the playing surface and there's a slight gap between the two halves so it's not like it needs to match up perfectly to look decent.

What I have seen thus far have been reupholstered with a speed cloth. What I meant was a custom logo. How much leeway should you tell a designer to use so the final product won't look uneven when replaced?

What I have seen thus far have been reupholstered with a speed cloth. What I meant was a custom logo. How much leeway should you tell a designer to use so the final product won't look uneven when replaced?

If you deal with @T_Chan he will print it so that it’ll line up nicely:

That is a really good design to work with a seam. The smaller repeating design helps disguise the seam whereas one big logo would telegraph the seam.If you deal with @T_Chan he will print it so that it’ll line up nicely:View attachment 306841View attachment 306842

SixSpeedFury

Full House

If you deal with @T_Chan he will print it so that it’ll line up nicely:View attachment 306841View attachment 306842

This is exactly what I mean. Thanks wonderpuddle!

Moxie Mike

Full House

What I have seen thus far have been reupholstered with a speed cloth. What I meant was a custom logo. How much leeway should you tell a designer to use so the final product won't look uneven when replaced?

If your discussing something like a giant detailed logo in the center of the table (ala center ice of a hockey arena), I wouldn't try to reupholster a Barrington table that way. I don't think you could get the logo halves to line up considering that the material needs to be stretched over the ends of the playing surface and stapled to the underside.

Now if we're discussing a repeating pattern like in @wonderpuddle's example, then getting the pattern lined up shouldn't be too difficult since there's plenty of excess material to get it lined up the way you want it.

Last edited:

Whenever I do a design for a cloth for a table with a fold, I do the artwork in 2 halves with plenty of extra space where the center of the table will be. Any logo, whether it's a pattern or a single large image isn't a problem.

Couple questions... but first just want to say how good of idea this is. I've been struggling with finding a table at a reasonable price with speed cloth, and not having the time to do a full table build.

- Where do you guys order the speed cloth from? And how much of it? I've seen it on Amazon but wasn't sure if thags the right place to order it.

- I'm a fan of classic looks, so I was going to go with green. Any issues with that? I've noticed a lot of people like blue.

- When applying the cloth, is it as simple as stapling one side, and then pulling the other side super tight, and then stapling that end? And then repeat for all sides? Cut excess off. Want to make sure it's on there smooth but also not rip it.

- How stable is it? Does require any reinforcement?

Moxie Mike

Full House

Couple questions... but first just want to say how good of idea this is. I've been struggling with finding a table at a reasonable price with speed cloth, and not having the time to do a full table build.

Thanks!

- Where do you guys order the speed cloth from? And how much of it? I've seen it on Amazon but wasn't sure if thags the right place to order it.

- I'm a fan of classic looks, so I was going to go with green. Any issues with that? I've noticed a lot of people like blue.

- When applying the cloth, is it as simple as stapling one side, and then pulling the other side super tight, and then stapling that end? And then repeat for all sides? Cut excess off. Want to make sure it's on there smooth but also not rip it.

- How stable is it? Does require any reinforcement?

Welcome to PCF

Barrington tables are a decent product and a solid value for the price... can comfortably seat 9 and are easily modifiable.

https://www.yourautotrim.com is a good source for the premium SSC. Texas Poker Supply (a PCF vendor) also has quality stuff. If you see the SSC that's 1/2 the price as others (like you find on Amazon), it's a lower quality fabric so buyer beware.

The Barrington table is 7 feet long. So the standard 9 ft roll is more than enough.

The vinyl is black, so any color you choose is going to be fine. That said, SSC does come in some brighter colors that people have expressed a disdain for - so I'd be conservative in your color choice unless you want to give your guests a migraine

Yes reupholstering the playing surface is pretty easy... I did mine in 90 minutes. Search PCF for 'Barrington' and read the walkthroughs people have been kind enough to post.

As to stability, it's an 8.5 out of 10. Very acceptable for the price but it can wobble a little bit if someone bumps into it with a little force.

The one thing you might one to think of is installing deeper cupholders. The ones that come with it are only about 1" deep, and we've had spills. I posted a thread about my project earlier this month.

jcooper911

Two Pair

Couple questions... but first just want to say how good of idea this is. I've been struggling with finding a table at a reasonable price with speed cloth, and not having the time to do a full table build.

Thanks!

- Where do you guys order the speed cloth from? And how much of it? I've seen it on Amazon but wasn't sure if thags the right place to order it.

- I'm a fan of classic looks, so I was going to go with green. Any issues with that? I've noticed a lot of people like blue.

- When applying the cloth, is it as simple as stapling one side, and then pulling the other side super tight, and then stapling that end? And then repeat for all sides? Cut excess off. Want to make sure it's on there smooth but also not rip it.

- How stable is it? Does require any reinforcement?

I got my cloth from amazon and it’s great.

Went with deep green and am v happy, deep navy or deep burgundy also classy.

I used cheap clamps to make sure cloth was stretched and ready for staple, but the way you suggest probably works.

Table doesn’t need reinforcement, just have 2 people put it up and fold away so you don’t stress the hinges you will have taken apart and reassembled...

Good luck and let me know any questions!

Last edited:

Forty4

Full House

With fall around the corner I should be recovering mine. Also debating on the deeper cup holders.

1A25R

Flush

Which foam thickness did you used under the speed cloth?

Moxie Mike

Full House

Which foam thickness did you used under the speed cloth?

It comes padded. All you need to do is peel the cloth off.

Done! Can't believe how good it looks compared to the original. Don't understand why they don't start doing this and charge and extra 50 bucks.

It definitely wasn't hard, just tedious. I'd say the worst parts were stapling the felt down (just so many damn staples)... And the end of putting everything back together. Not hard, just a pain. I'm not sure what others think, but I it's my opinion this shouldn't be done more than once. I think it would be too much for the wood to handle. I know others have asked if you could make the cup holders deeper, and you definitely could with the rigjt tools. My only concern would be the wood being able to handle that kind of beating.

I do have 1 problem tho. See the last picture. On one of the rails at the one end, the screws would not grab into the wood at all. I pushed with everything I had, and it wouldn't grab. My thought process was the holes were probably too big now for the screws. Does anyone have any suggestions to help this? It's probably more visual than anything. But if someone accidentally pulls there, it would be an issue. Maybe glue it down? Adhesive? Bigger screws? Other than that it's great and ready for my Friday game! Thanks to everyone past and present in this thread.

It definitely wasn't hard, just tedious. I'd say the worst parts were stapling the felt down (just so many damn staples)... And the end of putting everything back together. Not hard, just a pain. I'm not sure what others think, but I it's my opinion this shouldn't be done more than once. I think it would be too much for the wood to handle. I know others have asked if you could make the cup holders deeper, and you definitely could with the rigjt tools. My only concern would be the wood being able to handle that kind of beating.

I do have 1 problem tho. See the last picture. On one of the rails at the one end, the screws would not grab into the wood at all. I pushed with everything I had, and it wouldn't grab. My thought process was the holes were probably too big now for the screws. Does anyone have any suggestions to help this? It's probably more visual than anything. But if someone accidentally pulls there, it would be an issue. Maybe glue it down? Adhesive? Bigger screws? Other than that it's great and ready for my Friday game! Thanks to everyone past and present in this thread.

Fill the holes with a golf tee or wooden match sticks and cut them flush with the surface. You should then be able to tighten the screws.

Moxie Mike

Full House

I know others have asked if you could make the cup holders deeper, and you definitely could with the rigjt tools. My only concern would be the wood being able to handle that kind of beating.

I do have 1 problem tho. See the last picture. On one of the rails at the one end, the screws would not grab into the wood at all. I pushed with everything I had, and it wouldn't grab. My thought process was the holes were probably too big now for the screws. Does anyone have any suggestions to help this? It's probably more visual than anything. But if someone accidentally pulls there, it would be an issue. Maybe glue it down? Adhesive? Bigger screws? Other than that it's great and ready for my Friday game! Thanks to everyone past and present in this thread.

Deeper cupholders make a big difference. All you need to do is take the old ones out, then bore through the bottom with a hole saw (2 3/4" I think). On mine, there were 4 spots where the tubular legs were in the way - I just zipped them off with a sawzall outfitted with a metal cutting blade.

Walmart has the best price on the cupholders you need: https://www.walmart.com/ip/Trademark-Poker-Lot-Of-10-Stainless-Steel-Cup-Holders/21070419

As to your stripped out screw hole, you can fill it (spackle, bondo or some type of wood-filler product would probably be fine), wait for it to dry and then run your screw in, or move it over slighty.

If it were me, I'd probably just drill a quick pilot hole right beside the stripped out one and run your screw in.

Deeper cupholders make a big difference. All you need to do is take the old ones out, then bore through the bottom with a hole saw (2 3/4" I think). On mine, there were 4 spots where the tubular legs were in the way - I just zipped them off with a sawzall outfitted with a metal cutting blade.

Walmart has the best price on the cupholders you need: https://www.walmart.com/ip/Trademark-Poker-Lot-Of-10-Stainless-Steel-Cup-Holders/21070419

.

Do you have a picture of the deeper cup holder installed? I’m assuming you would need to take the cup holders out when folding the table?

Similar threads

- Replies

- 4

- Views

- 237

- Replies

- 11

- Views

- 482

- Replies

- 21

- Views

- 2K

- Replies

- 12

- Views

- 492

- Replies

- 14

- Views

- 477