You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flattening Warped Chips (7 Viewers)

- Thread starter ski_ex5

- Start date

ranger764

Flush

Rack came in yesterday. So much easier then lining up without it especially if you’re using the 43mm ceramics.

RadicusScout

Flush

You know, whenever I see pictures like this (with awesome, custom tooling correcting an issue I had no idea even existed) I have to remind myself that I found my way here to PCF to only look for a suitable replacement for my dice chips. Consider Pandora's box completely opened.Rack came in yesterday. So much easier then lining up without it especially if you’re using the 43mm ceramics. View attachment 662417

PlayerADK

Flush

Before and after

Still need some more cleaning done but man people weren't kidding about this yellow shit haha

Might just leave them as is, especially without an ultrasonic.

Still need some more cleaning done but man people weren't kidding about this yellow shit haha

Might just leave them as is, especially without an ultrasonic.

BirdCage

Flush

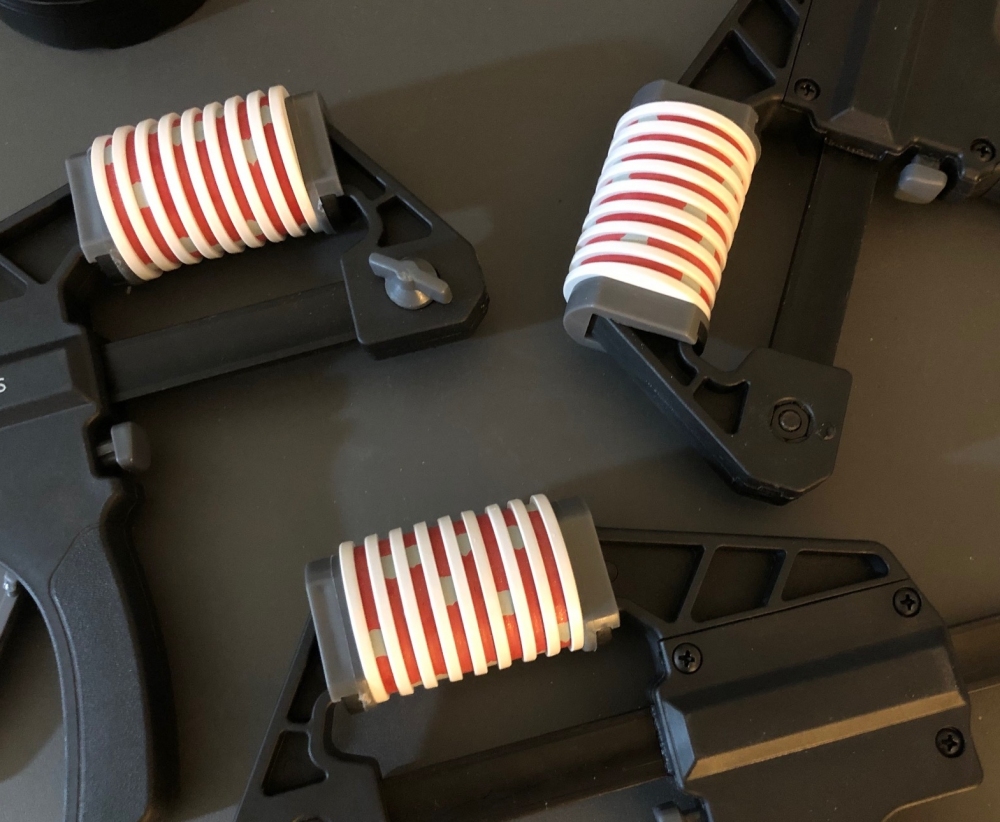

Four barrel solution.

ranger764

Flush

Damn, we’re those cincy quarters warped too?

BirdCage

Flush

Only about 50% of each rack. Not much, but a bit for sure.Damn, we’re those cincy quarters warped too?

Colquhoun

4 of a Kind

I’m finding most chips could use some flattening.

If I hold up a barrel to a bright light, and see light between the chips, I’m flattening them.

If I hold up a barrel to a bright light, and see light between the chips, I’m flattening them.

BirdCage

Flush

Five barrels at once, these used Cincy JACK $1’s had minor warpage. Only using pressure and time to flatten them a bit. OK if not perfect in the end.

OfficerLovejoy

Full House

I recommend involving some kind of temperature change. Even a few min clamped under a hairdryer might do the trick.

I did the same as you did for a few days and did not see much of an improovement without heating the chips up.

I did the same as you did for a few days and did not see much of an improovement without heating the chips up.

OfficerLovejoy

Full House

Has anybody tried to flatten ceramics yet?

I've got some Nevada Jack Skulls that are a few years old and time hasn't been kind to them.

I've got some Nevada Jack Skulls that are a few years old and time hasn't been kind to them.

Colquhoun

4 of a Kind

Wow, never seen a warped ceramic. I would think more heat would be required, but the amount needed may alter the ink? Also, the plastic in ceramics may be the type that cannot be reheated to soften. It may just get more brittle.Has anybody tried to flatten ceramics yet?

I've got some Nevada Jack Skulls that are a few years old and time hasn't been kind to them.

Tread lightly...

OfficerLovejoy

Full House

Yeah that's what I'm thinking too. More heat also means more stress on the clamp...

I've been using these and I don't think they can stand much more than the 50° Celsius I've been using for clays.

I've been using these and I don't think they can stand much more than the 50° Celsius I've been using for clays.

OfficerLovejoy

Full House

Here's what I'm talking about.

Interesting that you are heating up the ceramic spacers as well as the chips. Is that better? I just heat the chips. Let me know your thoughts. Thanks.

I think it works better, and I dont have to leave them in heat very long. 15 min topsInteresting that you are heating up the ceramic spacers as well as the chips. Is that better? I just heat the chips. Let me know your thoughts. Thanks.

Nanook

Full House

I like doing this too.Interesting that you are heating up the ceramic spacers as well as the chips. Is that better? I just heat the chips. Let me know your thoughts. Thanks.

I agree with the works better part. Heating the ceramic spacers gives you more time to get it all put together without the chips you intend to flatten cooling. Pre-heat the heating pad to 140 or 150°F. Once warm, lay everything out on one end of the heating pad and fold it over so the chips warm on both sides. Let it sit for 10 minutes, unfold the heating pad, stack the chips with the ceramic spacers in between each chip you want to clamp. Dump them all into the half round PVC, clamp and put them aside to cool for minimum of 45 min to an hour and you are good to go. Re-tighten clamps during the cooling process after 10 minutes or so 1x or 2x if you like. If not happy with the initial results then rinse and repeat. No need for the 43mm ceramics as 39 works great, but if you overheat the chips the 39mm ones can leave a mark. I have never seen any marks left @ 150°F, but I did try 170°F one time and did see some slight marks. Nothing very obvious, but visible enough that I would not go that high again. With 105 ceramic spacers and 4 clamps you can pretty much flatten constantly 20 chips at a time and do a lot quickly. I cut a piece of 1.5" PVC pipe about 7 inches long and in half. All you have to do is lay all 41 chips in there and they just fall right into place. I have now done over 1000 chips this way and it works really well and is very efficient. Here is what I use and what my production line looks like:I think it works better, and I dont have to leave them in heat very long. 15 min tops

Last edited:

Ok. I will heat the ceramics going forward.

Nanook

Full House

If you already have both, I don't think it will make any difference at all. If you are going to go out and buy something I would buy the quick grip type as opposed to the screw type. I have both and over all I much prefer the quick grip type as they are super easy and "quick" to tighten. Irwin is fine, but there are a bunch of other brands too that will all do just fine.I'm about to get a flattening set up (using the heating pad, not the oven). Is there a general preference between the Quick-Grip and the Powertech?

OfficerLovejoy

Full House

Too much pressure. Don't retighten after heating. Also getting 43mm spacers helps.

Colquhoun

4 of a Kind

I found tightening just until everything is snug is plenty. Do not keep squeezing the clamp. The less pressure you use, the less chance of damage.

I was amazed how little pressure still got the job done.

I was amazed how little pressure still got the job done.

Nanook

Full House

Changing the shape is a result of a combination of heat, pressure and time so you have over done 1 or more of the stated. From my experience, the thing that is most likely to cause damage is too much temperature. Light pressure of heavy pressure @ 150°F and you are going to get the same results. Crank up the temp to >= 170° and you are going to start to see a slight change to the shape of the chip. Crosshatching may get smoothed out or you might get a dimple or ridge along the edge of the chips etc.Anyone experienced dimpled edges after flattening chips? I did, wonder if I got them too hot…

OfficerLovejoy

Full House

OfficerLovejoy

Full House

To answer my own question:Has anybody tried to flatten ceramics yet?

I've got some Nevada Jack Skulls that are a few years old and time hasn't been kind to them.

Yes, you can!

Good amount of pressure and 20 min at 65° celsius. Let them cool in the clamps for at least an hour and you get this (untreated chips on the left, flattened on the right):

Caution:

These settings worked for ceramics which are more heat resistant than clays as far as I can tell.

My recipe for flattening Paulsons is 10 min at 50° celsius.

Last edited:

"And so it begins". Starting today on the mass flattening of some ASM Roman molds using the heating pad method. Chips were stored for a long time in a shed, none are bad warped but every barrel is a wobbler. Method is super easy, hoping to get some good results.

Colquhoun

4 of a Kind

I’ve heard ASM chips are far more susceptible to damage from heat, and that the flattening can work without hardly any at all. Curious to see your experience."And so it begins". Starting today on the mass flattening of some ASM Roman molds using the heating pad method. Chips were stored for a long time in a shed, none are bad warped but every barrel is a wobbler. Method is super easy, hoping to get some good results.

View attachment 761210

Similar threads

- Locked

Ends 11-10-24 at 7:30 PM Eastern Time

- Replies

- 4

- Views

- 268

- Locked

Ends 11-10-24 at 7:00 PM Eastern Time

- Replies

- 7

- Views

- 337