I have tried the no heat, just pressure method on these Romans with little effect. I have a couple of spare barrels to test on so starting out with 130f heating pad for 10 min and minimum clamp pressure for 1 hour coolng to start with.

Flattening Warped Chips (6 Viewers)

- Thread starter ski_ex5

- Start date

I’ve heard ASM chips are far more susceptible to damage from heat, and that the flattening can work without hardly any at all. Curious to see your experience.

I would use a bit of heat. Flattening old ASM type chips with clamps only risks causing fractures. Don't ask me how I know.

Initial results were good. Barrels are mostly flat/no more wobble except for a few of the chips that will require a second run to completely flatten.

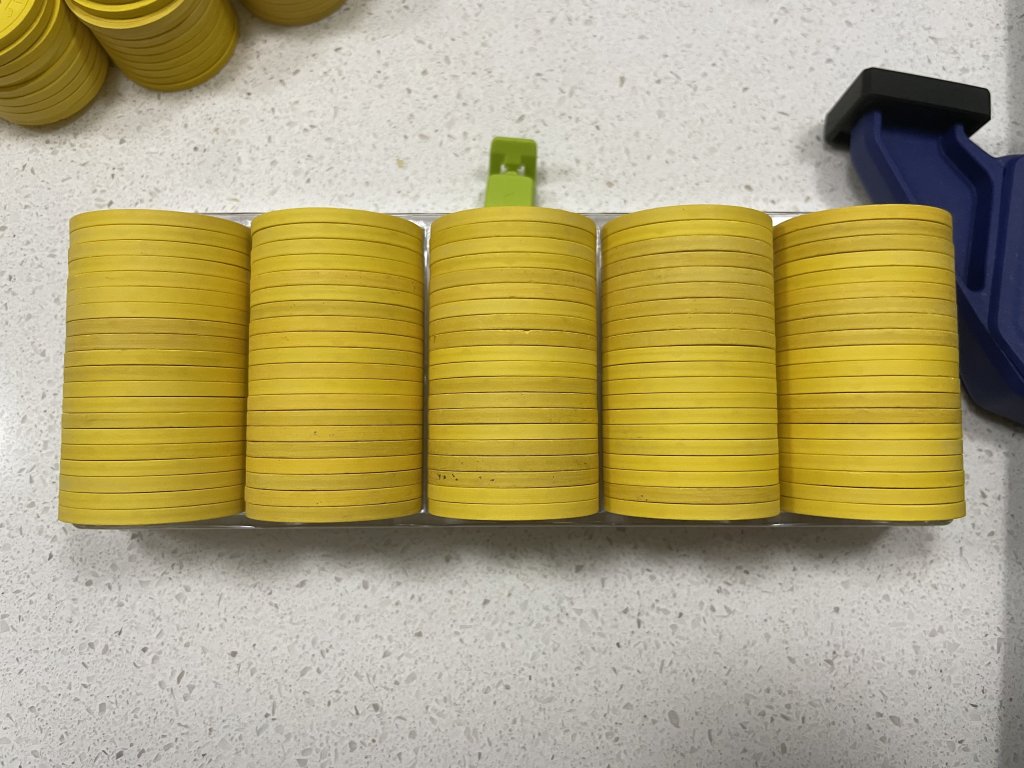

130f for 10-12 minutes and minimum clamp pressure showed no adverse effects on the chips especially the molding which tends to sit high on Roman molds. Using 43mm ceramic blanks and chip flattening racks from @One Eyed Dollar . I also ran a barrel of chips that had been already murdered/relabeled with gear labels & oiled without any adverse effects to labels.

For the chips needing a second run I'm going to increase the temp to 140f just to see if they can handle it.

130f for 10-12 minutes and minimum clamp pressure showed no adverse effects on the chips especially the molding which tends to sit high on Roman molds. Using 43mm ceramic blanks and chip flattening racks from @One Eyed Dollar . I also ran a barrel of chips that had been already murdered/relabeled with gear labels & oiled without any adverse effects to labels.

For the chips needing a second run I'm going to increase the temp to 140f just to see if they can handle it.

Ok...... this is why we test shit.

After the initial batch at 130f (for 10min) & minimum pressure we bumped the more obvious warped chips up to 140f (for 10min). Going back to check for issues we found a disappointing problem.

Obvious creasing on even the chips done at the lower (130f) temperature.

Thankfully we have a few more test subjects so the next steps are:

1: I have a barrell clamped up with no heat involved and am going to leave them for a couple of weeks to see if anything changes. We have tried this before but for a much shorter time 2-3 days and had little effect but we are going to leave them clamped for a longer time this time around.

2: Going to run a small batch at 60f for 10min & minimum pressure to see if we still get the creasing at the lower heat level.

After the initial batch at 130f (for 10min) & minimum pressure we bumped the more obvious warped chips up to 140f (for 10min). Going back to check for issues we found a disappointing problem.

Obvious creasing on even the chips done at the lower (130f) temperature.

Thankfully we have a few more test subjects so the next steps are:

1: I have a barrell clamped up with no heat involved and am going to leave them for a couple of weeks to see if anything changes. We have tried this before but for a much shorter time 2-3 days and had little effect but we are going to leave them clamped for a longer time this time around.

2: Going to run a small batch at 60f for 10min & minimum pressure to see if we still get the creasing at the lower heat level.

OfficerLovejoy

Full House

Do you heat the chips before clamping oder after?

I found that if I clamp the chips first just so they sit firm between their ceramic spacers and then apply the heat they don't get squished.

I appreciate the scientific work you're doing.

I found that if I clamp the chips first just so they sit firm between their ceramic spacers and then apply the heat they don't get squished.

I appreciate the scientific work you're doing.

Interesting,

No I'm following the plan of warming them up in the heating pad first along with the spacers and then clamping them up after 10min.

No I'm following the plan of warming them up in the heating pad first along with the spacers and then clamping them up after 10min.

Do you heat the chips before clamping oder after?

I found that if I clamp the chips first just so they sit firm between their ceramic spacers and then apply the heat they don't get squished.

I appreciate the scientific work you're doing.

Are you just wrapping the clamped barrel in the heating pad after clamping? Also what temps are you using?

OfficerLovejoy

Full House

I'm still using my stove since it can be set to pretty low temperatures.

So idk if it translates 1:1 to the process with a heating pad but I've seen members here wrapping their pads around already clamped up chips.

So idk if it translates 1:1 to the process with a heating pad but I've seen members here wrapping their pads around already clamped up chips.

OfficerLovejoy

Full House

These were done this way at 60° Celsius for 8 minutes and then letting them cool down in the clamp for about an hour.

Cool, but we are comparing apple to oranges here. You are flattening Paulsons & I'm doing ASM/CPC chips.

I may try a small batch where I pre-clamp them this way then apply the heat (wrap them with pad).

I'm pretty sure that the ASM/CPC's material doesn't like that amount of heat I'm using though.

I may try a small batch where I pre-clamp them this way then apply the heat (wrap them with pad).

I'm pretty sure that the ASM/CPC's material doesn't like that amount of heat I'm using though.

OfficerLovejoy

Full House

I've had the same creasing on paulsons after retightening the clamps when already hot. So not really apples and oranges more oranges and grapefruits.

Which clampI am a flattening machine these days.....

View attachment 659579

Do

You recommend? I got my blanks and I’m ready to start this madness, lol. I just need the heating pad and the clamps.

Colquhoun

4 of a Kind

Any small hand clamp will do… I use the Irwin “quick grip” clamps and some inexpensive knock-offs from Harbor Freight.Which clamp

Do

You recommend? I got my blanks and I’m ready to start this madness, lol. I just need the heating pad and the clamps.

Any clamp where you can control the pressure will do. But you won’t need too much pressure!

I agree with @Colquhoun. I use the quick grip clamps as well. For the heating pad make sure u get the extra long one and the series 700 (not the 500) so u get the temp gauge. Good luck!Which clamp

Do

You recommend? I got my blanks and I’m ready to start this madness, lol. I just need the heating pad and the clamps.

Just ordered the heating pads. Anyone have a recommendation on where to get the ceramic blanks?

Colquhoun

4 of a Kind

Reach out to @BR Pro Poker via PM, they have the blanksJust ordered the heating pads. Anyone have a recommendation on where to get the ceramic blanks?

Thanks!!!Reach out to @BR Pro Poker via PM, they have the blanks

I'm really appreciative of all the info shared in this thread, it inspired me to undertake the flattening of my Fun Nites. I'm about half way through and the results are phenomenal.

I can't add anything to the time/temp info already stated but I did find it was easy to use the slats of our plant stand to center the chips in a trigger clamp. Hope this adds a little value to the thread.

I can't add anything to the time/temp info already stated but I did find it was easy to use the slats of our plant stand to center the chips in a trigger clamp. Hope this adds a little value to the thread.

ranger764

Flush

Damn I don’t remember seeing this. Those look greatBefore and after

Still need some more cleaning done but man people weren't kidding about this yellow shit haha

Might just leave them as is, especially without an ultrasonic.

View attachment 684472

View attachment 684474

Thanks everyone for the tips and tricks here. The heating pad was a game changer!! I use the hand clamps similar to what goldfish used and they won’t over press the chips.

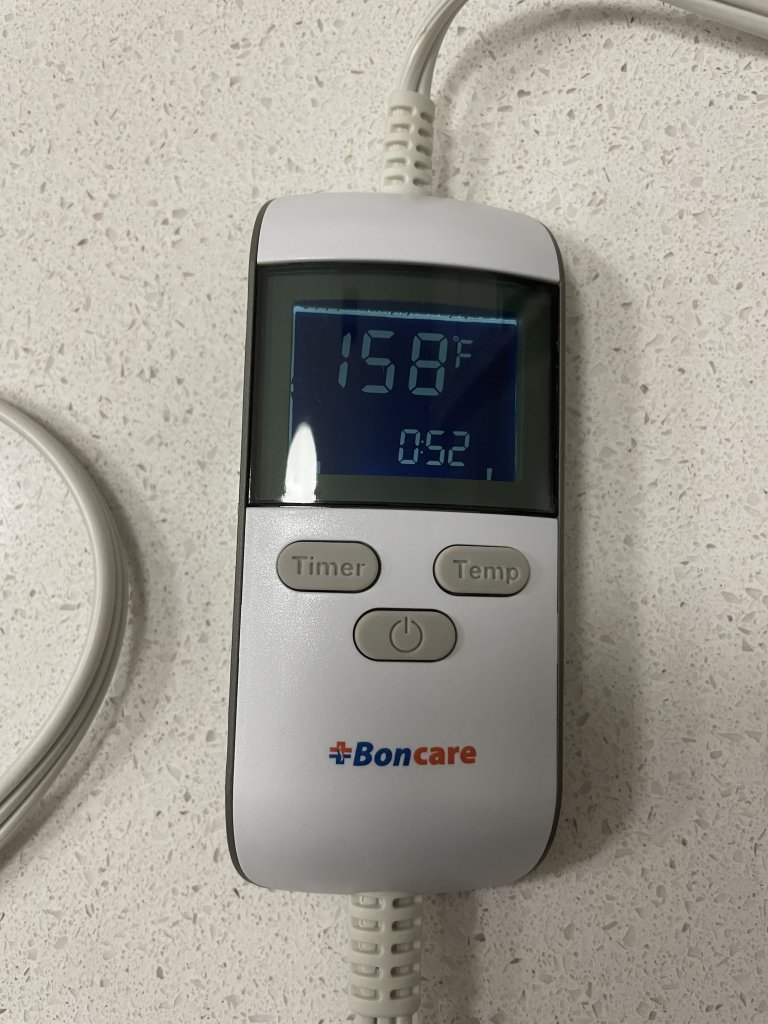

10 mins at 158 to heat the chips and ceramic blanks covered in the blanket, then into the press for 40-50 mins wrapped in the heating blanket. I let them cool for 30-40 mins on the counter and then remove them from the clamp.

Turned this

Into this

10 mins at 158 to heat the chips and ceramic blanks covered in the blanket, then into the press for 40-50 mins wrapped in the heating blanket. I let them cool for 30-40 mins on the counter and then remove them from the clamp.

Turned this

Into this

I need more blanks so just ordered some. Also don’t have the chip stackers yet since I just ordered those so I set it up manually.

I place an empty pot on top to keep the chips in closer contact with the blanket.

Heat for 10-15 mins covered and then I place them into the clamp.

I manually line them up

Then back under the blanket for 40-50 mins

After you take them out of the blanket, let them cool in the clamp for at least 30 mins until cool to the touch before you release the clamp and take the chips out. Repeat the process for the next batch

I place an empty pot on top to keep the chips in closer contact with the blanket.

Heat for 10-15 mins covered and then I place them into the clamp.

I manually line them up

Then back under the blanket for 40-50 mins

After you take them out of the blanket, let them cool in the clamp for at least 30 mins until cool to the touch before you release the clamp and take the chips out. Repeat the process for the next batch

Last edited:

Man I wish I knew how to do all this lol where do I find the ceramic blanks for 39mm n 43mm chips ?

Nanook

Full House

Be careful. You will wind up damaging your chips at that temp. 158F is too hot. 140F is plenty.

The rack I did seemed ok. Maybe because I didn’t clamp them too tight. I did another batch last weekend at 149 and they seemed to work just as well. Will try 140 next timeBe careful. You will wind up damaging your chips at that temp. 158F is too hot. 140F is plenty.

Nanook

Full House

Sometimes you need to look really carefully. Take a loop and look at the crosshatching closely before and after flattening.

Colquhoun

4 of a Kind

Agreed. And it’s surprising how little pressure is needed for that warm chip to become flat. It’s WAY too easy to crank down too much on those clamps.Sometimes you need to look really carefully. Take a loop and look at the crosshatching closely before and after flattening.

I’ve found the perfect pressure is just enough so that the chips don’t fall out of the clamp. That’s not much.

BRPro - make sure you size-up (use 43mm blanks for 39mm chips, 47mm blanks for 43mm chips).Man I wish I knew how to do all this lol where do I find the ceramic blanks for 39mm n 43mm chips ?

I took my first stab at flattening some chips this weekend using the heating pad method...works great! Thanks to all for the detailed instructions. I did notice the barrel height was slightly lower after flattening as compared to an un-flattened barrel. I presume this is because they are now sitting super flat stacked on each other whereas the other barrel is raised slightly higher due to the small warps in the chips. I did not see any signs of edge dimpling or other issues on the newly flat chips, but did want to ask if this condition is typical of others' experience. Thanks for the information.

TS

TS

OfficerLovejoy

Full House

Yes, this is typical. The warped chips take up more space then the flat ones.I took my first stab at flattening some chips this weekend using the heating pad method...works great! Thanks to all for the detailed instructions. I did notice the barrel height was slightly lower after flattening as compared to an un-flattened barrel. I presume this is because they are now sitting super flat stacked on each other whereas the other barrel is raised slightly higher due to the small warps in the chips. I did not see any signs of edge dimpling or other issues on the newly flat chips, but did want to ask if this condition is typical of others' experience. Thanks for the information.

TS

OneGearManySpeeds

Flush

@BGinGA and any others reading. Looking for 11 or 22 blank ceramics. Also open to any stackers or holders to help align. I'm half way through reading this entire thread and seems like the best approach so far. If no one has any like the quote above... where's the best place buy the flattest ceramic blanks? I've got a Hodge podge of older pink fracs I'd like to flatten up. thx.Or pm me. I bought a rack on eBay, and easily have about three-four times as many as I'll ever need.

Similar threads

- Locked

Ends 11-10-24 at 7:30 PM Eastern Time

- Replies

- 4

- Views

- 275

- Locked

Ends 11-10-24 at 7:00 PM Eastern Time

- Replies

- 7

- Views

- 342