LotsOfChips

Flush

So some time ago I read a thread from @Taghkanic where he was discussing how the standard "Stadium" or "Oval" shaped table had pretty poor sight lines (players at certain seats can't easily see players at some other seats), and after playing at a bunch of different tables, I pretty much agree with him.

https://www.pokerchipforum.com/threads/table-shapes-a-bit-of-a-rant.22942/

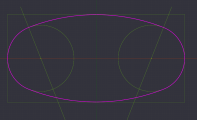

After looking at some simple Ellipse based tables, I found that the ends were a bit too pointed for my taste. So when I decided to build my own table, I wanted to use the "Super-Ellipse" or Lamé Curve shaped design, as mentioned by @Taghkanic in the above noted thread.

https://en.wikipedia.org/wiki/Superellipse

This is different than a simple ellipse in that rather than having just a Major (a) and Minor (b) Axis to define the curve, you can adjust and vary the shape of the table by altering the "n" value of the mathematical equation that defines the curve:

x = a * ( cos(t) ) ^ ( 2 / n ) * sign(( cos(t) ))

y = b * ( sin(t) ) ^ ( 2 / n ) * sign(( sin(t) ))

The issue that I struggled with was that unlike "Oval" or Ellipse builds, there are no simple woodworking jigs to accurately lay out, draw or cut a super-ellipse curve on a full sheet of plywood.

I asked in a thread on this forum for suggestions on how to draw out and cut the shapes, but didn't really come up with any methods that would provide the accuracy and the flexibility to change shapes that I was looking for.

https://www.pokerchipforum.com/threads/how-the-heck-do-you-cut-a-super-ellipse.105025/

Given my level of OCD, I realized that I wouldn't be happy with free-handing things or getting "close enough" and then sanding things to line up afterwards. So I decided that using a CNC machine would be about the only way that I could pull this off. I looked online for home shop CNC machines that could cut full sheets of plywood, and stumbled across the V1 Engineering Lowrider. It uses 3D printed materials for many of the parts, and the designer has posted all of the plans and files online for free. Total cost for all of the hardware (including the 3d filament but not including the table, router and end mills, or my new 3D printer) is around $450 US.

I built the Lowrider version 3, but there is a new and more capable version 4 that has just been released. Here is a link to my build thread on the V1E Forum

https://forum.v1e.com/t/introducing-big-red-lowrider-3/45509

Next up was learning how to use 3D modelling to create the table design. I used AutoDesk Fusion, which has a free license for hobbyists and small business users. There was a bit of a learning curve, but after a bit of trial and error I was able to come up with a design that allows me to quickly alter:

Here's a few examples:

"n" = 2.2 96" x 48" 8 player w/ Jumbo Cup Holders and 6" Rail

Same table, but changing "n" to 2.4 (less pointed on the ends)

Here's a smaller version

n" = 2.2 84" x 44" 8 player w/ Regular Cup Holders and 4.5" Rail

and again the less pointed "n" = 2.4 version:

Here's the 84 x 44 version (N = 2.2) with the cup holders on the ends:

and a 10 player version

A view of the bottom, that shows all of the screw and bolt placement

And lastly a cross section of the table surface and rail

I still have a little bit more modelling to do (adding folding table legs, cup rings, etc.), but the model is close to finished. I am going to start laying out the flat pieces in a couple of weeks in order to generate the "g-code" commands for the CNC. After that, I need to teach myself Adobe Illustrator, so that I can prepare my custom Chanman cloth design. Who knows how long that will take...

https://www.pokerchipforum.com/threads/table-shapes-a-bit-of-a-rant.22942/

After looking at some simple Ellipse based tables, I found that the ends were a bit too pointed for my taste. So when I decided to build my own table, I wanted to use the "Super-Ellipse" or Lamé Curve shaped design, as mentioned by @Taghkanic in the above noted thread.

https://en.wikipedia.org/wiki/Superellipse

This is different than a simple ellipse in that rather than having just a Major (a) and Minor (b) Axis to define the curve, you can adjust and vary the shape of the table by altering the "n" value of the mathematical equation that defines the curve:

x = a * ( cos(t) ) ^ ( 2 / n ) * sign(( cos(t) ))

y = b * ( sin(t) ) ^ ( 2 / n ) * sign(( sin(t) ))

The issue that I struggled with was that unlike "Oval" or Ellipse builds, there are no simple woodworking jigs to accurately lay out, draw or cut a super-ellipse curve on a full sheet of plywood.

I asked in a thread on this forum for suggestions on how to draw out and cut the shapes, but didn't really come up with any methods that would provide the accuracy and the flexibility to change shapes that I was looking for.

https://www.pokerchipforum.com/threads/how-the-heck-do-you-cut-a-super-ellipse.105025/

Given my level of OCD, I realized that I wouldn't be happy with free-handing things or getting "close enough" and then sanding things to line up afterwards. So I decided that using a CNC machine would be about the only way that I could pull this off. I looked online for home shop CNC machines that could cut full sheets of plywood, and stumbled across the V1 Engineering Lowrider. It uses 3D printed materials for many of the parts, and the designer has posted all of the plans and files online for free. Total cost for all of the hardware (including the 3d filament but not including the table, router and end mills, or my new 3D printer) is around $450 US.

I built the Lowrider version 3, but there is a new and more capable version 4 that has just been released. Here is a link to my build thread on the V1E Forum

https://forum.v1e.com/t/introducing-big-red-lowrider-3/45509

Next up was learning how to use 3D modelling to create the table design. I used AutoDesk Fusion, which has a free license for hobbyists and small business users. There was a bit of a learning curve, but after a bit of trial and error I was able to come up with a design that allows me to quickly alter:

- Table Length ("a")

- Table Width ("b")

- Table Shape ("n")

- Rail Width

- Cup Holder Size (Jumbo, Regular or None)

- # of cupholders (8 or 9 players)

- Location of Cup Holders (In the middle and ends, or staggered away from the ends)

Here's a few examples:

"n" = 2.2 96" x 48" 8 player w/ Jumbo Cup Holders and 6" Rail

Same table, but changing "n" to 2.4 (less pointed on the ends)

Here's a smaller version

n" = 2.2 84" x 44" 8 player w/ Regular Cup Holders and 4.5" Rail

and again the less pointed "n" = 2.4 version:

Here's the 84 x 44 version (N = 2.2) with the cup holders on the ends:

and a 10 player version

A view of the bottom, that shows all of the screw and bolt placement

And lastly a cross section of the table surface and rail

I still have a little bit more modelling to do (adding folding table legs, cup rings, etc.), but the model is close to finished. I am going to start laying out the flat pieces in a couple of weeks in order to generate the "g-code" commands for the CNC. After that, I need to teach myself Adobe Illustrator, so that I can prepare my custom Chanman cloth design. Who knows how long that will take...

Last edited: