I would magic eraser those edges.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ultrasonic Chip Cleaning (17 Viewers)

- Thread starter ski_ex5

- Start date

wickedwonka121

Flush

You can also try the mars plastic eraser from staedtler.Looking for some advice. I bought two racks of off-white IOC Bossier City T1s from one seller and three barrels from another seller. It wasn't until after I oiled all of them (derp) that I realized that the three barrels are noticeably darker / yellower. These are hot stamps btw.

What would be your strategy if you wanted to bring the darker chips closer to the lighter chips? I have melamine pads (MagicEraser). I do not have an ultrasonic cleaner. It's hard to capture in a photo, but here is a lighter chip between some darker ones:

Thanks for any guidance. @allforcharity tagging you cause it sounds like you have a lot of hot stamp experience.

Edit: Sounds like hydrogen peroxide is good for chip stains. I will try that in a few weeks.

Rooster410

3 of a Kind

works nicely on dirty gun (black powder) components also

I purchased this one from amazon:

https://www.amazon.com/VEVOR-Commer...+instrument+apparatus+cleaning,aps,365&sr=8-3

I use dawn with warm water and it does the job. I can clean up to 300-400 chips at a time, My suggestion is to use your hands to stir them around occasionally while in the water during the ultrasonic cleaning. Remove chips from sonic cleaner and rinse water over the chips while still in the strainer/basket and then lay out flat on a towel. place another towel over top and hand dry them in-between the towels.

https://www.amazon.com/VEVOR-Commer...+instrument+apparatus+cleaning,aps,365&sr=8-3

I use dawn with warm water and it does the job. I can clean up to 300-400 chips at a time, My suggestion is to use your hands to stir them around occasionally while in the water during the ultrasonic cleaning. Remove chips from sonic cleaner and rinse water over the chips while still in the strainer/basket and then lay out flat on a towel. place another towel over top and hand dry them in-between the towels.

Attachments

paulkersey

Two Pair

Has anyone had luck finding Sodium Metisilicate in Canada?

I might know a guy...Has anyone had luck finding Sodium Metisilicate in Canada?

Has anyone had luck finding Sodium Metisilicate in Canada?

Have you tried Lowe's or Home Depot for degreaser (you want powder). I just realized I bought the Red Devil stuff off Amazon US.

paulkersey

Two Pair

Following up on this especially since it's been a while. I'm interested in getting feedback regarding the typical quantity cleaned per cycle. Recently, I've been experimenting with doing one barrel at a time to potentially improve outcomes. However, I'm not sure this is necessary. Would like to hear from others about how many you typically load into the basket per cycle while still getting really good results.

I've actually found that even doing a barrel at a time might be too much depending on the mold and how dirty they are. Exceptionally dirty roulettes or RHC typically come out with about 20% needing to go back in if I do 20 at a time. When I do 10 at a time, I have a 99% success rate for those 10 and none of them need additional cleaning.Following up on this especially since it's been a while. I'm interested in getting feedback regarding the typical quantity cleaned per cycle. Recently, I've been experimenting with doing one barrel at a time to potentially improve outcomes. However, I'm not sure this is necessary. Would like to hear from others about how many you typically load into the basket per cycle while still getting really good results.

Then when doing some THC chips that are moderately dirty, 20 at a time is fine. But any more than that and I definitely don't think that the cavitation effect can reach all services effectively. I once got impatient and tried 40, and although most came out clean, I could definitely see where some were sticking together even during the salad spinner rotation process.

I always did 40 max. I never noticed any better results going less, but found more would hinder the results.Following up on this especially since it's been a while. I'm interested in getting feedback regarding the typical quantity cleaned per cycle. Recently, I've been experimenting with doing one barrel at a time to potentially improve outcomes. However, I'm not sure this is necessary. Would like to hear from others about how many you typically load into the basket per cycle while still getting really good results.

jamesjkim

Flush

Probably depends on the size of your US and basket. I do a barrel at a time and lengthen the duration depending on how dirty the chips are.

I've actually found that even doing a barrel at a time might be too much depending on the mold and how dirty they are. Exceptionally dirty roulettes or RHC typically come out with about 20% needing to go back in if I do 20 at a time. When I do 10 at a time, I have a 99% success rate for those 10 and none of them need additional cleaning.

Then when doing some THC chips that are moderately dirty, 20 at a time is fine. But any more than that and I definitely don't think that the cavitation effect can reach all services effectively. I once got impatient and tried 40, and although most came out clean, I could definitely see where some were sticking together even during the salad spinner rotation process.

I had some chips that weren't looking their best, especially those Avalon yellows that I now use as my WTHC fracs. Tried using the "standard" method of two barrels at a time, but some stubborn ones didn't get much better. So, I scaled it back, started doing just a barrel or even just 10 at a time. Worked like a charm. Wanted to see if anyone else had the same issue with certain chips. And oh boy, I even tried this battery-operated brush cleaner thinking it would get good results. Nope, just ended up annoying the s$%t out of me, and it barely made a difference, even with OxiClean. Lesson learned: nothing beats the ultrasonic cleaner.

Probably depends on the size of your US and basket. I do a barrel at a time and lengthen the duration depending on how dirty the chips are.

I use the 3 liter version with that big green basket that most use. I forgot the capacity but it fills up the ultrasonic from end to end when in use. I used to do 30-40 seconds for chips that were barely dirty. I noticed that I had to extend that to about a minute, sometimes even a minute and a half for the stubborn stuff.

Has anyone noticed any issues with the chips following ultrasonic cleaning? I'll admit I haven't inspected them super closely, but I've heard some talk about it potentially causing some degradation. Yet, personally, I haven't seen any evidence of that. Just wondering if anyone else has had the same experience.

1 to 2 barrels, depending on how dirty, how many I have to clean and how much time I have.

jamesjkim

Flush

I also haven't looked super closely but I've done up to 2 mins at 43*C on filthy chips and haven't had any issues. They generally need a good oiling afterwards but no noticeable issues otherwise. I'm also using 3L US.Has anyone noticed any issues with the chips following ultrasonic cleaning?

Yup, I've definitely noticed that smaller batches can produce better results. If anything, smaller batches allows you to run them for shorter amounts of time. And the less time in the ultrasonic, the better.I had some chips that weren't looking their best, especially those Avalon yellows that I now use as my WTHC fracs. Tried using the "standard" method of two barrels at a time, but some stubborn ones didn't get much better. So, I scaled it back, started doing just a barrel or even just 10 at a time. Worked like a charm. Wanted to see if anyone else had the same issue with certain chips. And oh boy, I even tried this battery-operated brush cleaner thinking it would get good results. Nope, just ended up annoying the s$%t out of me, and it barely made a difference, even with OxiClean. Lesson learned: nothing beats the ultrasonic cleaner.

I use the 3 liter version with that big green basket that most use. I forgot the capacity but it fills up the ultrasonic from end to end when in use. I used to do 30-40 seconds for chips that were barely dirty. I noticed that I had to extend that to about a minute, sometimes even a minute and a half for the stubborn stuff.

Has anyone noticed any issues with the chips following ultrasonic cleaning? I'll admit I haven't inspected them super closely, but I've heard some talk about it potentially causing some degradation. Yet, personally, I haven't seen any evidence of that. Just wondering if anyone else has had the same experience.

I have had zero issues with degradation. Although some chips like ASMs will disintegrate, most paulsons are fine. That said, depending on the solution that I use, the heat, and the time, there can be varying degrees of fading. But, a nice oiling afterward and they're back to their beautiful pre-wash shine.

I use the 6L since it has an extra transducer.

Yup, I've definitely noticed that smaller batches can produce better results. If anything, smaller batches allows you to run them for shorter amounts of time. And the less time in the ultrasonic, the better.

I have had zero issues with degradation. Although some chips like ASMs will disintegrate, most paulsons are fine. That said, depending on the solution that I use, the heat, and the time, there can be varying degrees of fading. But, a nice oiling afterward and they're back to their beautiful pre-wash shine.

I use the 6L since it has an extra transducer.

I may eventually upgrade to the 6L for that reason. Better results even if I'm using the same quantity of chips.

As far as heat and time goes, I usually hover around the 43ºC mark, 1-1.5 mins. It's actually shocking what the oil does afterwards. They look even better than when they were chalky and new. The colors pop. I recall coming across a post somewhere suggesting that applying oil may help the subsequent cleaning process by reducing the stubbornness of the grime accumulated.

Bluegrass Poker

Flush

So someone help me out here, I’ve seen varying comments about using the US on CPC chips.

Is that just on CPC or does it apply to their predecessor ASM?

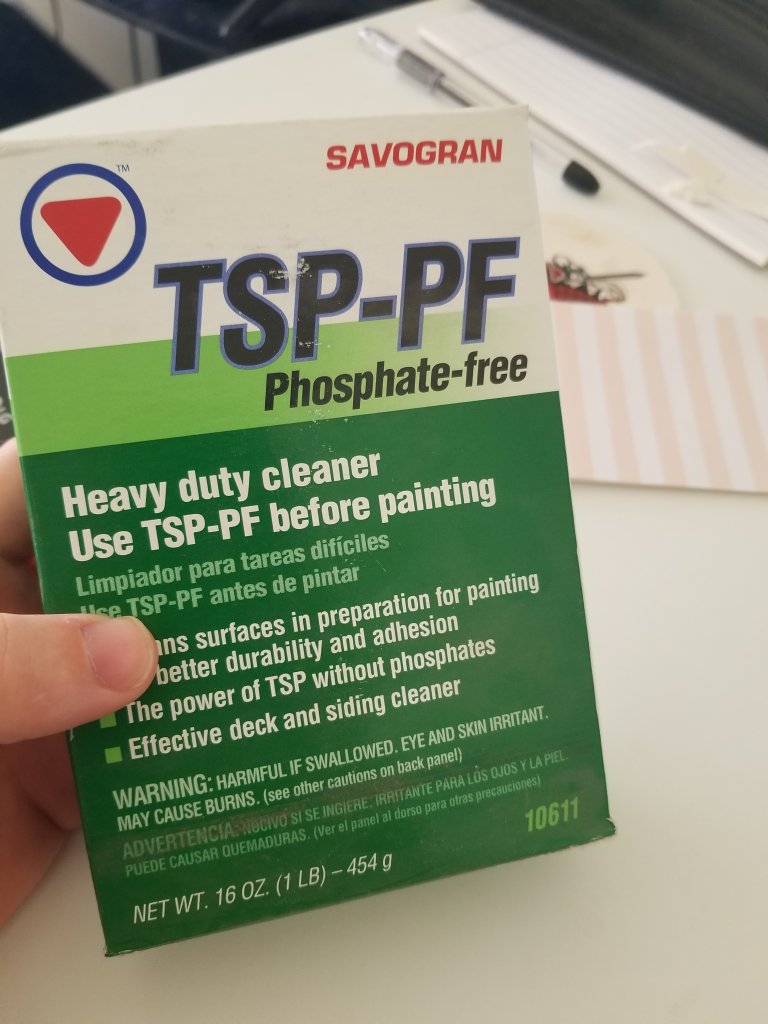

Also some have said US is fine for CPC as long as you don’t use TSP.

Thanks.

Is that just on CPC or does it apply to their predecessor ASM?

Also some have said US is fine for CPC as long as you don’t use TSP.

Thanks.

First off, all of the posts here that mention TSP always mean faux TSP. I don't think real TSP is used to clean any of the chips as it would most likely destroy them.So someone help me out here, I’ve seen varying comments about using the US on CPC chips.

Is that just on CPC or does it apply to their predecessor ASM?

Also some have said US is fine for CPC as long as you don’t use TSP.

Thanks.

Everything I've read says not to use the ultrasonic with any type of TSP on ASM or CPC chips. I personally have tried using simple green with Burt / BC Wills and it didn't have much of an effect. I switched to faux TSP and they came out great.

You can search the comments here and most people say don't do any of this with ASM/CPC chips and I tend to agree. But you will also find the random post that says that they have some method that works.

Why?the less time in the ultrasonic, the better.

That has nothing to do with ultrasonic, and everything to do with the detergent being used (i.e. TSP.)Although some chips like ASMs will disintegrate

Correct, ultrasonic is fine for both ASM and CPC chips (basically the same chip composition) as long as you don't use TSP.Is that just on CPC or does it apply to their predecessor ASM?

Also some have said US is fine for CPC as long as you don’t use TSP.

What? That is simply incorrect. I've used actual TSP (trisodium phosphate, not just "TSP-brand cleaner") for years and it only destroys ASM/CPC chips.all of the posts here that mention TSP always mean faux TSP. I don't think real TSP is used to clean any of the chips as it would most likely destroy them.

Starting to think Cunningham's Law is at work here.

The ultrasonic will fade the chips the longer they are in there. My point was that if you put more chips in at once, then they're going to inherently stick together more. For the ultrasonic to be able to reach all the surfaces, they're just going to have to be in there longer, which means that some surfaces are exposed a lot more than others.Why?

Yes, and I said that simple green along with the ultrasonic does not harm chips usually. Normally when people talk about ultrasonic cleaners, they're also using TSP with them.That has nothing to do with ultrasonic, and everything to do with the detergent being used (i.e. TSP.)

I believe I even made a post where I commented that I tried simple green with old BCW chips, and after not being very effective, I tried fake TSP which worked pretty well.

Oh really!? When you search any of the threads here, the vast majority of them always say to use the fake TSP as real TSP tends to destroy the chips. But if the fake stuff works great and is easier on the chip, why not use that? Why risk it with real TSP?What? That is simply incorrect. I've used actual TSP (trisodium phosphate, not just "TSP-brand cleaner") for years and it only destroys ASM/CPC chips.

It also does a decent job of destroying hot stamps on Paulsons.What? That is simply incorrect. I've used actual TSP (trisodium phosphate, not just "TSP-brand cleaner") for years and it only destroys ASM/CPC chips.

I disagree. The temperature and composition of the solution has a WAY bigger effect on fading than does the ultrasonic itself. It also depends on the color of the chips to start with -- reds and purples are far more susceptible to fading (from heat) than, say, black.The ultrasonic will fade the chips the longer they are in there.

Again, I disagree. "Real TSP tends to destroy the chips" is just wrong information.When you search any of the threads here, the vast majority of them always say to use the fake TSP as real TSP tends to destroy the chips. But if the fake stuff works great and is easier on the chip, why not use that? Why risk it with real TSP?

BTW one reason to use actual TSP is when the fake stuff isn't available, or is considerably more expensive (both of which are true in my local hardware stores.)

Yes, true, although it's only removing the foil. Results vary from stamp-vintage to stamp-vintage though... it seems inevitably that if you're *trying* to remove the foil, it's stubborn, but if you're hoping to preserve it, it vanishes quicklyIt also does a decent job of destroying hot stamps on Paulsons.

Okay, I think we're getting things a bit confused here. My point was that when most people talk about using an ultrasonic cleaner, it's usually in conjunction with some sort of chemical solution and heat.I disagree. The temperature and composition of the solution has a WAY bigger effect on fading than does the ultrasonic itself. It also depends on the color of the chips to start with -- reds and purples are far more susceptible to fading (from heat) than, say, black.

When I first got my HSI snappers (The ones that had that weird pink/ yellow crap on them) I did a test where I left them in the ultrasonic with just water for about 30 minutes. And they came out like nothing had ever happened to them. They weren't cleaner, but they definitely were not faded.

However, you do the same test with any type of TSP-based solution and or warm water, and they will definitely come out faded. We've all also had that chip that accidentally falls out of the salad spinner and you don't find it for a good 20 minutes. And that thing comes out essentially bleached and looking really weird.

So I stand by my statement that less time in the ultrasonic is better, But that's with the understanding that most people are using their ultrasonic cleaners with some type of cleaning solution and even just the heat that builds up from running it.

Really? I mean it destroys hot stamps. It can dissolve certain types of chips. It just doesn't seem worth the risk. I'm sure there are some chips where it's okay. In almost every single cleaning thread, the recommendation is to use the fake TSP.Again, I disagree. "Real TSP tends to destroy the chips" is just wrong information.

BTW one reason to use actual TSP is when the fake stuff isn't available, or is considerably more expensive (both of which are true in my local hardware stores.)

I hear you about the fake stuff being harder to acquire and possibly more expensive. But I guess that's what Amazon is for? Also, my local Home Depot carries an off brand of the fake stuff for only a few dollars per box.

I had that experience once - I was trying to remove hot stamps, they got stubborn.Yes, true, although it's only removing the foil. Results vary from stamp-vintage to stamp-vintage though... it seems inevitably that if you're *trying* to remove the foil, it's stubborn, but if you're hoping to preserve it, it vanishes quickly

Let me ask you something. In my experience, cleaning with TSP and with TSP substitutes tends to dry out chips. I’ve never used an ultrasonic, but out of curiosity, I’m wondering if the ultrasonic itself dries out chips, or if it’s a combination of the ultrasonic and the TSP. Because the dryest chips I’ve ever gotten have all been ultrasonicced; but I don’t know what agents were used in the ultrasonic.

See my post right above this. I've run Paulson chips in an ultrasonic with just water for 30+ minutes and they came out like nothing had ever happened. And after running it for 30 minutes, the water did warm up. So even though the heater wasn't on, it wasn't cold tap either.Let me ask you something. In my experience, cleaning with TSP and with TSP substitutes tends to dry out chips. I’ve never used an ultrasonic, but out of curiosity, I’m wondering if the ultrasonic itself dries out chips, or if it’s a combination of the ultrasonic and the TSP. Because the dryest chips I’ve ever gotten have all been ultrasonicced; but I don’t know what agents were used in the ultrasonic

The solution is really what's going to do it. And it does do it. Usually lose one or two chips for every 100 that I put in because they fall out of the salad spinner and stay in for 5 minutes or 10 minutes until I see them. And then they've changed in color so much. There's no hope for them.

I guess that depends on where to live. TSP is illegal in my state, so I can’t get it easily at all. The only reason I have any experience with it (and not just the substitute) is because I happened to have an old box laying around from many years ago.I hear you about the fake stuff being harder to acquire and possibly more expensive. But I guess that's what Amazon is for? Also, my local Home Depot carries an off brand of the fake stuff for only a few dollars per box.

Okay, but you mention only color. Do you think the fading and the dryness go hand in hand? Maybe they do with TSP, I’m not sure. But I’ve cleaned chips with oxi that have faded (a fading never to be restored by oil) but not all dried out.See my post right above this. I've run Paulson chips in an ultrasonic with just water for 30+ minutes and they came out like nothing had ever happened. And after running it for 30 minutes, the water did warm up. So even though the heater wasn't on, it wasn't cold tap either.

The solution is really what's going to do it. And it does do it. Usually lose one or two chips for every 100 that I put in because they fall out of the salad spinner and stay in for 5 minutes or 10 minutes until I see them. And then they've changed in color so much. There's no hope for them.

So I just mix this in with the dogfood? Neat!

Similar threads

- Replies

- 2

- Views

- 271