You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

We need orders! (1 Viewer)

- Thread starter David Spragg

- Start date

There are no molds here except the 17 in use and the Ewing & Roulette.

All others were either donated to museums or returned to their owners years ago.

All others were either donated to museums or returned to their owners years ago.

I 've done my best; and wish the best to my beloved CPC

improviseallday

Flush

When are the deadlines for the next CSQ/FDL runs?

Yeah, I would definitely not give up the license if I were you. Have you actively solicited casinos? Not sure you have production capacity for a huge order, but maybe for a small place?As I mentioned before, if I make the Ewing Mold available then I have to give up the Nevada Gaming Licence which I don't really want to do yet.

I keep thinking about it but I'm not ready.

Sorry if there is clearly stated somewhere, but when I search for it I find conflicting info.

Is the A-mold still always available? And what are the order minimums for A-mold?

Is the A-mold still always available? And what are the order minimums for A-mold?

A-mold always available.Sorry if there is clearly stated somewhere, but when I search for it I find conflicting info.

Is the A-mold still always available? And what are the order minimums for A-mold?

Check the CPC website for details.

Very possible. Let's say however you add a $1 per chip premium to each chip sold on the new mold. Depending on the number of orders, you'd make your money back in a couple of years in all likelihood.It was the grinder manufacturers that fixed it. That's all they do. It's impossible to resurrect a worn out mold. The middle of all the cups collapse so there is nothing left of it. In any case all worn out molds have long since been donated to museums.

Trying to create a new mold now that none of the technology used to create the originals exists anymore is very risky. You'd have an outlay of up to $75,000 for something that might not even work. Even if it did we could never ever get our money back.

TKEUofM

Flush

I was thinking about a Large Crown order. What is the timing window for that?

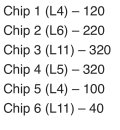

Ditto…I can’t wait for the Mockport Jockeys to arrive. L11…worth it.

Attachments

MichaelBubly

Flush

The more concerning part, I imagine, is the "Might not work" part. Hard to risk a significant investment for break even return if there is a realistic chance it just may not work at all.Very possible. Let's say however you add a $1 per chip premium to each chip sold on the new mold. Depending on the number of orders, you'd make your money back in a couple of years in all likelihood.

Too much talk, when CPC is offering a train-load of possibilities, and many people here ignorantly and naively insist on being ripped-off by second-hand Paulson-mongers (meaning "clever" individual members)

Or the explosion of state wide “social club” card rooms but they are probably off limits as well since it’s a Nevada gaming issue license.Yeah, I would definitely not give up the license if I were you. Have you actively solicited casinos? Not sure you have production capacity for a huge order, but maybe for a small place?

And honestly they could go w any mold. But I’d be soliciting them hard.

Pippa

4 of a Kind

- Joined

- Aug 13, 2020

- Messages

- 7,021

- Reaction score

- 9,413

Why not make a PCF CPC custom set????

Tournament and cash

Tournament and cash

Not a smart ass question, if the molds wear out and you have a finite number of molds, when do you project you will be unable to continue manufacturing chips? Or would they just be no molds once the current molds are done?

louBdub

4 of a Kind

This.Not a smart ass question, if the molds wear out and you have a finite number of molds, when do you project you will be unable to continue manufacturing chips? Or would they just be no molds once the current molds are done?

My curiosity is peaked at the $75K to make a mold. My smooth brain just thinks it’s a CNC cup, hardened, and finished to needs.

Where’s the other $73,500 going? I’m not being a smartass either, but I’m obviously missing a HUGE piece of this mold magic manufacturing process.

Last edited:

I wrote a rant against Paulson NAGBs but then deleted it so I can take this in a more constructive direction.

@David Spragg I take you at your word that new molds are not economically viable (right now anyway). Would new colors and spot patterns be possible? If for example, some enterprising PCFers decided to conduct a group buy for a bulk order with a proprietary set of new colors + spots from CPC (instead of continually going back to the corporate monopolistic well of Paulson GPI NAGBs) would that be possible? Maybe for a premium?

okay...so this was still a little ranty.

@David Spragg I take you at your word that new molds are not economically viable (right now anyway). Would new colors and spot patterns be possible? If for example, some enterprising PCFers decided to conduct a group buy for a bulk order with a proprietary set of new colors + spots from CPC (instead of continually going back to the corporate monopolistic well of Paulson GPI NAGBs) would that be possible? Maybe for a premium?

okay...so this was still a little ranty.

My scrown order is ready to go in when back from vacation in December!

AlbinoDragon

Flush

I'm trying to find it via search and am having no luck but David has mentioned in the past that it''s not as simple as machining a new cup. It's produced using a hardened steel (?) piece called a hob (I think that's the name) which then makes the cups.This.

My curiosity is peaked at the $75K to make a mold. My smooth brain thoughts just think it’s a CNC cup, hardened, and finished to needs.

Where’s the other $73,500 going? I’m not being a smartass either, but I’m obviously missing a HUGE piece of this mold magic manufacturing process.

Definitely not a CNC job and apparently a technique that's not used much anymore. Finding someone who could produce new hobs and cups would be difficult, let alone the expense in making such items, therefore the $75k price tag.

louBdub

4 of a Kind

I'm trying to find it via search and am having no luck but David has mentioned in the past that it''s not as simple as machining a new cup. It's produced using a hardened steel (?) piece called a hob (I think that's the name) which then makes the cups.

Definitely not a CNC job and apparently a technique that's not used much anymore. Finding someone who could produce new hobs and cups would be difficult, let alone the expense in making such items, therefore the $75k price tag.

This sheet mold is what costs $75,000?

Or these?

Yall rich people gotta keep this man in business while I collect quarters to make an eventual set, damnit!

AlbinoDragon

Flush

Yes, the tooling to make the hobs and then make those cups that go into that plate are $75k.

Last edited:

I’m sorry, I know there’s so much wrong in just ignorantly questioning the experts on this but I just can’t believe this art is that forgotten or that infeasible to reproduce. We are better at shaping large amounts of harder metals more precisely and efficiently than we have ever been before. It’s not like we’re searching for a dye recipe from 6,000 years ago to make one type of blue. This technology was produced within living memory and again, it’s something where the science has progressed very farYes, the tooling to make the hobs and then make those cups that go into that plate are $75k.

While I agree with all of the above… cpc does already have many outstanding molds we are pretty spoiled with.

Now a couple new colors or pattern and I’ll throw in to the kickstarter.

Now a couple new colors or pattern and I’ll throw in to the kickstarter.

AlbinoDragon

Flush

I trust David's word that this is expensive and not an easy thing to do as he knows the equipment and has researched what I would take to make new hobs and cups.I’m sorry, I know there’s so much wrong in just ignorantly questioning the experts on this but I just can’t believe this art is that forgotten or that infeasible to reproduce. We are better at shaping large amounts of harder metals more precisely and efficiently than we have ever been before. It’s not like we’re searching for a dye recipe from 6,000 years ago to make one type of blue. This technology was produced within living memory and again, it’s something where the science has progressed very far

It would have already happened if it wasn't a large financial outlay.

Nobody manufactures things like this anymore. There are more efficient and technologically advanced ways of making things today. The problem is that modern technology doesn't play well with the older technology at CPC that is used to make our chips. It'd be great if it were as simple as a CNC mill and some designs. I have mold ideas I'd love to see produced.

I think it's more that for a smaller company like CPC that doesn't have as much economy of scale to produce one-off molds that work with their current equipment and to do so is prohibitively expensive. The new technology and techniques maybe work for newer chip-making equipment that Paulson/GPI uses, and they're likely able to produce new molds that work with their equipment much cheaper (or have customers willing to pay for them). New casinos that want house molds are still able to get them made, but both GPI and the casinos have much deeper pockets too.I’m sorry, I know there’s so much wrong in just ignorantly questioning the experts on this but I just can’t believe this art is that forgotten or that infeasible to reproduce. We are better at shaping large amounts of harder metals more precisely and efficiently than we have ever been before. It’s not like we’re searching for a dye recipe from 6,000 years ago to make one type of blue. This technology was produced within living memory and again, it’s something where the science has progressed very far

What we really need is a reference page that covers the response to the above. It’s been asked and answered multiple times and if folks can’t find it in a search, then we should probably hook David up with a perma page we can reference.

Similar threads

- Replies

- 44

- Views

- 5K

- Replies

- 80

- Views

- 7K

- Replies

- 2

- Views

- 163